News / Blog

2026 Top Trends in Electronic Capacitors for Future Innovations?

As we enter a new era of technological evolution, electronic capacitors emerge as key components in driving innovation. Renowned expert Dr. Susan Li, a leading figure in capacitor technology, once remarked, “The future of electronic capacitors lies in their ability to adapt and improve energy efficiency.” This insight is pivotal as industries seek to enhance performance and sustainability.

The landscape of electronic capacitors is shifting rapidly. Innovations in materials and designs promise improved energy storage and efficiency. For instance, advancements in organic materials and nanotechnology are reshaping how these devices function. Companies are investing heavily in research and development to keep pace. However, some challenges remain. Not all innovations lead to immediate practical applications.

The future may hold surprises. Experts predict a blend of traditional and new technologies in electronic capacitors. While progress is promising, it requires caution and thoughtful engineering. As the industry evolves, learning from past mistakes and successes will be essential. Embracing change can drive advancements. Yet, it can also lead to unforeseen complications that need addressing.

Emerging Technologies Driving Electronic Capacitor Innovations in 2026

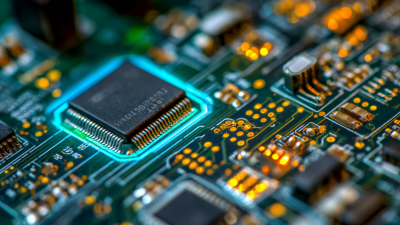

The landscape of electronic capacitors is evolving rapidly. By 2026, several emerging technologies are shaping this field. Innovations in materials technology play a critical role. Advanced polymers and ceramics are being researched for better performance and reliability. These materials promise higher capacitance values and smaller sizes. They enable more compact designs for electronic devices.

New manufacturing techniques are also transforming the industry. 3D printing is gaining traction, allowing for complex capacitor designs. This process can reduce waste and lower production costs. However, challenges remain in achieving high precision. Researchers are exploring ways to enhance the quality of printed components. The integration of smart materials is another exciting trend. Capacitors that can adapt to changing environments will be crucial in many applications. Yet, questions remain about their durability and long-term stability.

Sustainability is a pressing concern as well. The industry is looking for eco-friendly alternatives to traditional materials. This shift is essential for reducing environmental impact. Nevertheless, viable options are still limited. Striking a balance between performance and sustainability poses significant challenges. As these technologies advance, the future of electronic capacitors holds great potential. The journey will require continuous innovation and critical evaluation.

Sustainability Trends Impacting the Development of Electronic Capacitors

Sustainability is reshaping the electronic capacitors industry. The global demand for eco-friendly components is rising. According to a recent report, the market for green capacitors is expected to reach $5 billion by 2028, growing at a significant rate.

Recyclability and energy efficiency are in focus. Manufacturers are exploring biodegradable materials and recycling methods. This shift could reduce electronic waste, which reached 53.6 million metric tons globally in 2019. However, challenges remain. There is a lack of standardized processes for recycling capacitors. This inconsistency can hinder sustainability efforts.

Innovation in production methods is also essential. The push for lower carbon emissions is prompting companies to invest in renewable energy for manufacturing processes. Reports suggest that companies using sustainable practices see up to 20% reduction in production costs. However, the initial investment in advanced technologies can be daunting for smaller players in the market. Balancing these economic pressures with environmental goals is complex yet crucial.

2026 Top Trends in Electronic Capacitors for Future Innovations - Sustainability Trends Impacting the Development of Electronic Capacitors

| Trend | Description | Impact on Sustainability | Projected Adoption Rate (%) |

|---|---|---|---|

| Green Manufacturing | Focus on eco-friendly materials and processes in capacitor production. | Significantly reduces carbon footprint and resource consumption. | 75 |

| Miniaturization | Reduction in size of capacitors while maintaining or improving performance. | Less material usage leads to less waste and environmental impact. | 80 |

| Recyclable Materials | Development of fully recyclable electronic capacitors. | Promotes circular economy and reduces landfill waste. | 70 |

| High-energy Density Capacitors | Increasing energy storage capability per unit volume and weight. | Enables more efficient use of energy resources. | 65 |

| Smart Capacitors | Integration of sensors for monitoring performance in real-time. | Enhances efficiency and prolongs lifecycle, reducing waste. | 60 |

Key Materials Advancements for Next-Generation Capacitors

The world of electronic capacitors is on the brink of transformation. Key materials are driving next-generation innovations. The focus is shifting to advanced dielectrics, such as high-permittivity polymers. These materials promise increased energy density and improved performance in various applications.

Researchers are exploring new fabrication techniques. Nanostructured alternatives show potential in enhancing capacitor efficiency. However, challenges remain in scalability and cost-effectiveness. It’s a delicate balancing act between innovation and practical implementation. Furthermore, environmental concerns over material sourcing must be addressed.

Recycling and sustainability are gaining importance. Developing biodegradable options could reshape the market. While these advancements are promising, the path ahead is not without obstacles. Industry players must navigate this evolving landscape carefully, with an eye toward both innovation and responsibility.

Applications of High-Performance Capacitors in Modern Electronics

High-performance capacitors are essential in modern electronics. They play a critical role in power supply stabilization. These components help regulate voltage and enhance efficiency. A capacitor's performance reflects its ability to store and release energy quickly.

In various applications, these capacitors support advanced technologies. For instance, in electric vehicles, they enable rapid energy transfer. This is crucial for acceleration and braking systems. Their use in renewable energy solutions is also notable. They help manage energy fluctuations from solar and wind sources.

Despite their advancements, challenges remain. The manufacturing process for high-performance capacitors can be complex. New materials and designs require ongoing research. Additionally, reliability under extreme conditions is still a concern. These factors highlight the need for continued innovation in this field.

Challenges and Solutions in the Manufacturing of Advanced Capacitors

The manufacturing of advanced capacitors faces numerous challenges. Quality control is often a significant hurdle. Inconsistent materials can lead to uneven performance. Testing methods may fail to reveal hidden defects. These issues demand urgent attention.

There is also the challenge of scaling up production. As demand grows, maintaining quality becomes harder. Factories may struggle to keep pace. This can result in subpar components entering the market. Innovations in automation and quality assurance are essential yet not always feasible.

Furthermore, environmental regulations add layers of complexity. Compliance can slow down output and inflate costs. Manufacturers must balance eco-friendliness with efficiency. Striking this balance is crucial for sustainable advancements. Every step taken must be carefully scrutinized. In the quest for innovation, learning from failures is key.

Related Posts

-

Top Capacitors vs Resistors: Key Differences and Applications Explained

-

Why Electronic Capacitors Are Essential for Modern Electronics

-

Maximize Efficiency: Top Trends in Electronic Components Purchase for 2024

-

Unlocking Innovation: How Electronic Components Drive the Future of Technology

-

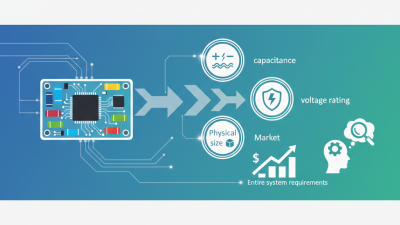

Essential Tips for Choosing the Right Electronic Capacitors for Your Projects

-

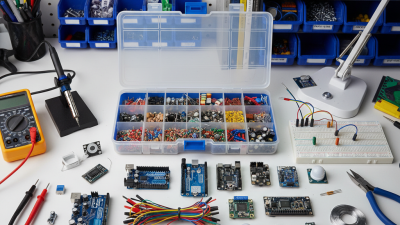

Top 10 Electronic Parts You Need for Your DIY Projects