News / Blog

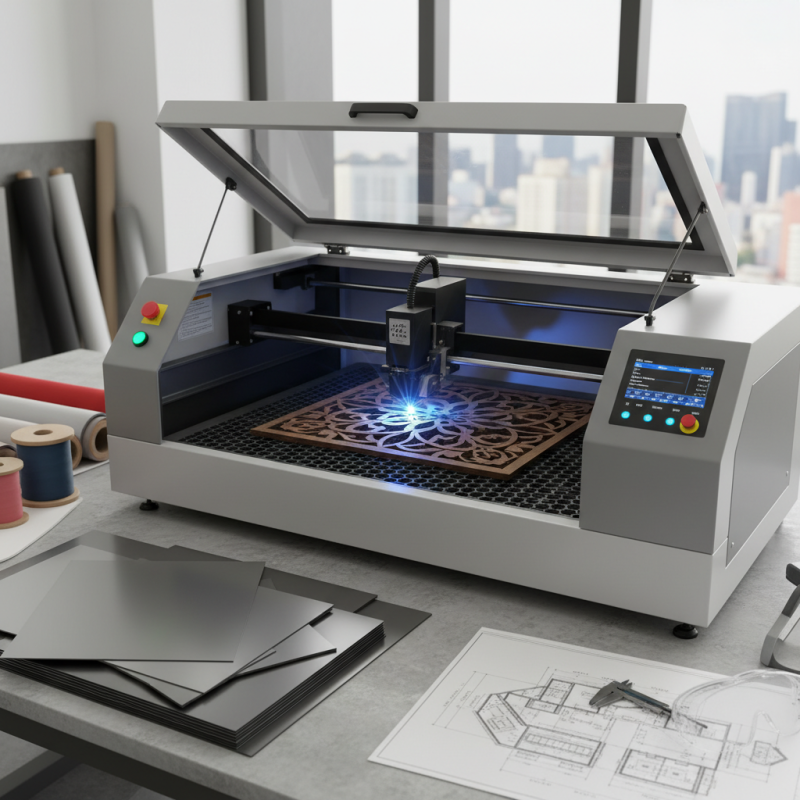

What is the Best Laser Cutting Machine for Your Needs?

Choosing the right laser cutting machine can be a daunting task. Many options are available, each with unique features. It's crucial to know your needs before investing.

Different projects require different machines. For instance, thick materials need powerful lasers. On the other hand, delicate designs may thrive with precision models. Understanding your material and design type is key.

Sometimes, users overlook important specifications. Speed, bed size, and wattage matter greatly. A machine that excels in one area may fall short in another. Reflecting on your priorities can help avoid regrets. Assessing your requirements carefully ensures you make the best choice for your laser cutting machine.

What to Consider When Choosing a Laser Cutting Machine

Choosing the right laser cutting machine for your needs requires careful consideration. First, evaluate the materials you plan to cut. Different machines handle various materials differently. For example, CO2 laser machines excel with non-metals like wood and acrylic, while fiber lasers are better for metals. According to a report by Grand View Research, the laser cutting market is expected to reach $5 billion by 2025. This growth highlights the increasing demand for versatile machines.

Next, think about the required cutting thickness. Machines vary in their cutting capabilities. Many can cut materials up to 20mm thick, but some advanced models can slice through 50mm or more. It’s crucial to match the machine’s power with your project needs. Consider the operational costs too. Operating a high-powered machine may result in increased electricity bills and maintenance costs. Data from TechSci Research suggests that the operational efficiency of a laser cutting machine is a key factor for businesses aiming to maximize productivity.

Remember to factor in the software compatibility as well. Not all machines come with user-friendly software. Complex programs can add to training time. The design process might require adjustments if the software isn’t intuitive. Ultimately, striking the right balance between features, cost, and usability is important. It's a journey that requires reflection on your unique requirements and future projects.

Types of Laser Cutting Technologies: CO2 vs. Fiber vs. YAG

When deciding between laser cutting technologies, understanding the core differences is crucial. CO2 lasers use a gas mixture and are widely used for cutting non-metal materials. They excel in cutting wood, acrylic, and plastics. Reports suggest that CO2 lasers dominate about 40% of the market. They provide high-quality cuts but can be slower on thicker materials compared to their counterparts.

On the other hand, fiber lasers have gained significant traction. They utilize solid-state technology and are highly efficient for metal materials. Their speed and precision outperform CO2 lasers in many metal cutting applications. Recent industry data indicates that fiber lasers account for nearly 30% of the laser cutting equipment market. While they are more cost-effective over time, the initial investment can be steep.

YAG lasers, while not as prevalent, still hold value in specialized applications. They are ideal for delicate tasks but lack the versatility of CO2 and fiber options. Each technology comes with unique challenges. Finding a balance between cost, functionality, and material compatibility remains a key area for manufacturers and users alike.

Key Specifications: Power, Speed, and Accuracy Explained

When choosing a laser cutting machine, key specifications like power, speed, and accuracy matter greatly. Power determines the thickness of materials you can cut. A high-power laser is essential for cutting metals. According to industry reports, lasers above 100W can effectively cut through 10mm steel. But, more power often means more operational costs.

Speed plays a crucial role in productivity. Faster machines can increase output but may compromise precision. A report from the Laser Institute states that machines operating at 3 m/min can improve efficiency by 40% compared to those at 1 m/min. However, it's vital to ensure that increased speed does not lead to lower quality cuts or excessive wear on components.

Accuracy is equally critical, especially in industries requiring detailed work. A precision rate of ±0.01 mm is often ideal for intricate designs. Inconsistent cutting can lead to faults, wasting materials and time. It’s necessary to assess whether the technology chosen can maintain accuracy while meeting speed and power needs. Balancing these specifications can be challenging. Cutting-edge features often come at a higher price, pushing users to evaluate their actual needs versus desires.

What is the Best Laser Cutting Machine for Your Needs? - Key Specifications

| Machine Type | Power (W) | Speed (mm/min) | Accuracy (mm) | Material Compatibility |

|---|---|---|---|---|

| CO2 Laser Cutter | 40-150 | 600-2000 | 0.1 | Wood, Acrylic, Glass |

| Fiber Laser Cutter | 500-4000 | 2000-5000 | 0.05 | Metal, Fabric |

| Diode Laser Cutter | 1-10 | 300-1000 | 0.1 | Wood, Paper, Leather |

| UV Laser Cutter | 20-100 | 1000-3000 | 0.02 | Glass, Plastic, Electronics |

Material Compatibility: Which Laser Cutter Works for Your Needs?

Choosing the right laser cutting machine hinges significantly on material compatibility. Different machines serve various materials best. Whether you're working with wood, acrylic, metal, or fabric, each requires specific laser settings and technology. For instance, CO2 lasers excel at cutting non-metal materials, while fiber lasers are ideal for metals. Understanding these distinctions helps in making an informed decision.

**Tip:** Always test the machine with sample materials. This will give you a clearer idea of the potential output and quality. Ensure that your chosen laser cutter can handle the thickness and type of material you want to work with. It's disappointing to find out too late that your machine cannot cut through the material you planned to use.

Some users might underestimate the importance of ventilation when cutting certain materials. Burning plastic or wood can release harmful fumes. Ensure your workspace has appropriate exhaust systems. This is often overlooked, but it’s crucial for safety. Consider investing in a good ventilation setup, even if it seems like an extra expense. You might find it worth the investment in the long run.

Cost Analysis: Budgeting for Purchase and Maintenance of Laser Cutters

When considering the purchase of a laser cutting machine, cost is a crucial factor. The initial investment can vary significantly based on features and power. A budget might range from a few thousand to tens of thousands of dollars. It's essential to assess your specific needs. Higher capabilities often mean higher costs. But is that worth it for your projects?

Maintenance is another critical aspect that impacts your budget. Regular upkeep ensures the machine operates efficiently. Costs can include replacement parts and servicing. It's easy to overlook these expenses during the purchasing process. Setting aside a portion of your budget for maintenance is wise. It can prevent surprises later on. Some users may underestimate these costs.

Ultimately, reflecting on your long-term needs helps in budgeting. Think about the materials you'll work with and the machine's workload. These factors will influence both the purchase and maintenance costs significantly. It’s not just about buying a machine. It's about sustaining its performance for years to come.