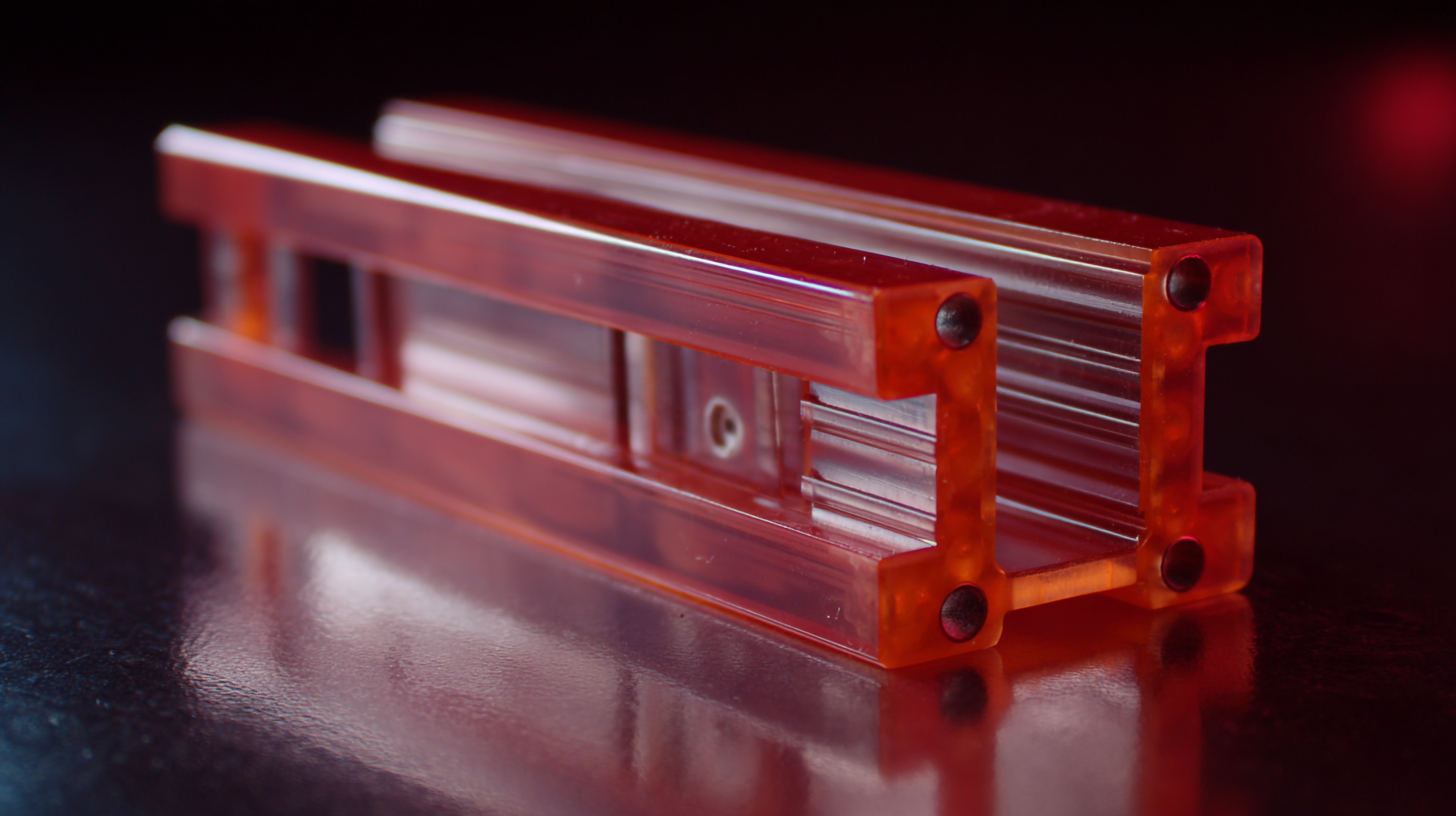

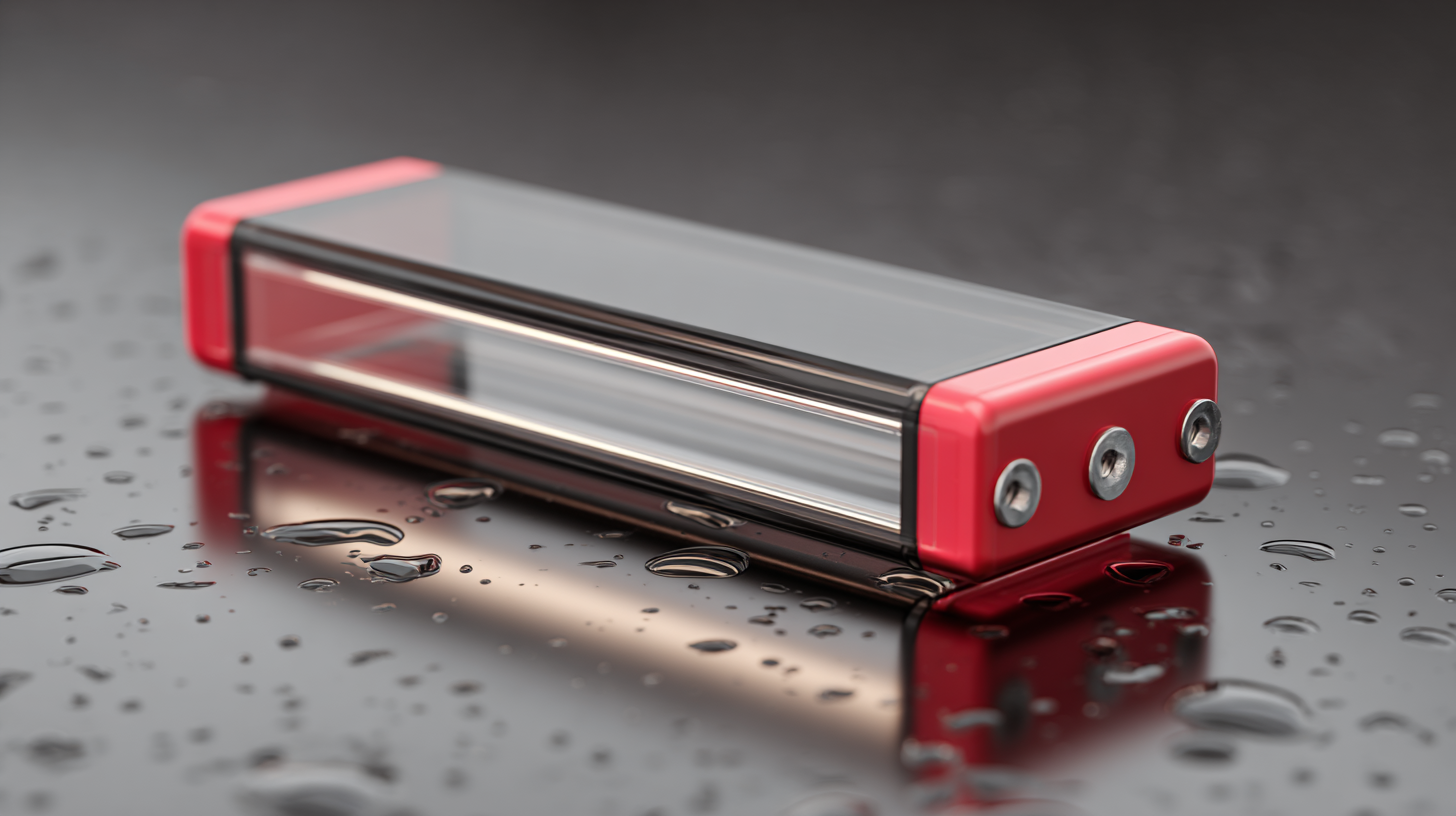

In today's rapidly advancing technological landscape, the plastic rectangular connector plays a crucial role across various industries, providing essential solutions for complex electronic systems. According to a report by Mordor Intelligence, the global connector market is projected to grow at a CAGR of 6.2% from 2021 to 2026, underscoring the increasing demand for reliable connectivity solutions.

Plastic rectangular connectors, known for their lightweight and versatile design, are preferred in sectors such as automotive, aerospace, and consumer electronics. The durability and cost-effectiveness of these connectors not only enhance product performance but also streamline the manufacturing process. As businesses seek to optimize their operations and embrace innovation, understanding the significance of plastic rectangular connectors becomes imperative. This blog will outline 10 compelling reasons why investing in the best plastic rectangular connector is essential for your business success.

Plastic rectangular connectors, known for their lightweight and versatile design, are preferred in sectors such as automotive, aerospace, and consumer electronics. The durability and cost-effectiveness of these connectors not only enhance product performance but also streamline the manufacturing process. As businesses seek to optimize their operations and embrace innovation, understanding the significance of plastic rectangular connectors becomes imperative. This blog will outline 10 compelling reasons why investing in the best plastic rectangular connector is essential for your business success.

When selecting the best plastic rectangular connectors for your business, understanding key technical specifications is crucial. Firstly, material quality matters significantly; top-tier plastic connectors are typically made from durable thermoplastics that offer excellent resistance to environmental factors and mechanical stress. Look for connectors that boast high-temperature resistance and low moisture absorption, which are essential for maintaining performance under varying conditions. Additionally, the connector's insulation properties play a vital role in preventing electrical leakage and ensuring reliable operations.

Another important technical aspect to consider is the connector's pin count and arrangement. The number of pins directly affects the connector's capability to handle multiple signals and power requirements, which is crucial for complex applications in industries such as telecommunications and automotive. Furthermore, contact plating materials can influence conductivity and corrosion resistance, with options like gold or nickel plating providing enhanced durability and performance. By focusing on these specifications, businesses can make informed decisions that lead to improved efficiency and long-term reliability in their applications.

When selecting the right plastic rectangular connector for your specific needs, it's essential to consider various factors that can significantly impact your product's performance. One of the first aspects to evaluate is the connector's material. Ensure that the plastic used is durable and suitable for the environment in which the connector will operate, whether it be in high-temperature settings or humid conditions.

Tip 1: Be mindful of the connector's compatibility with the devices it will connect. Check for industry standards and specifications to ensure a secure fit and reliable connection. This step can help avoid costly errors during installation or operation.

The design also plays a crucial role in connector selection. Look for features such as locking mechanisms or sealing options that provide added security and resistance against environmental factors. An ergonomic design can enhance usability, making it easier for your team to install and maintain the connectors.

Tip 2: Consider the supplier's reputation and customer support. Choose a supplier known for quality assurance and post-purchase assistance, which can be invaluable if issues arise or if you need customization for specific applications.

By focusing on these crucial attributes, you can make an informed decision that supports your business's unique needs and goals.

When it comes to connecting various components in your business, the installation of plastic rectangular connectors can significantly streamline your processes. A step-by-step installation guide is invaluable for ensuring that these connectors are used effectively. According to a report by Allied Market Research, the global connector market is projected to reach $81.65 billion by 2027, underscoring the importance of reliable connections in various industries. Proper installation of plastic rectangular connectors not only enhances durability but also promotes optimal performance of electronic devices, which is essential for maintaining operational efficiency.

To begin the installation process, make sure you have the right tools at your disposal, including a soldering kit and wire strippers. Start by stripping the wires to the appropriate length and inserting them into the connector. A study from Research and Markets reveals that incorrect installation can lead to failures, costing businesses up to 10% of their annual revenue. Thus, adhering to precise installation guidelines is crucial. Once secured, ensure that the connectors are tightly fitted to avoid any potential disconnections that could disrupt workflow or damage sensitive equipment. By following these steps, your business can achieve reliable connections that are essential for long-term success.

When it comes to plastic rectangular connectors, troubleshooting common issues can make a significant difference in maintaining your business's operational efficiency. One prevalent problem is poor connectivity caused by inconsistent connections, often due to wear and tear. Opting for high-quality plastic rectangular connectors can mitigate this issue, enhancing reliability and ensuring minimal downtime. Additionally, the resistance to environmental factors such as moisture and dust in quality connectors ensures longevity and consistent performance, which is vital for any business reliant on these components.

In the ongoing evolution of connection technologies, innovative solutions like panel-mount USB-C ports address common challenges faced with traditional connectors. USB-C’s versatility with the USB4 protocol not only simplifies connections but also improves data transfer speeds and power delivery, thereby reducing potential interruptions in business operations. By integrating such advancements into existing systems, businesses can avoid frequent troubleshooting stages associated with older connector types, thus streamlining processes and improving overall efficiency. Adopting these modern solutions is essential for staying competitive in today’s fast-paced environment.

Maintaining and extending the life of your plastic rectangular connectors is crucial for ensuring reliable performance and reducing operational costs. According to a recent report from the National Electrical Manufacturers Association, over 70% of connector failures can be attributed to improper maintenance. Implementing best practices, such as regular inspection and cleaning, can significantly enhance the longevity of these connectors. Ensuring that connectors are free from dust and moisture can prevent corrosion and degradation, which are major contributors to connector failure.

Moreover, design principles that emphasize adaptability and disassembly can further optimize the usability of connectors in various applications. A study on reversible timber connection systems highlighted the advantages of designing for adaptability, which can also be applied to plastic connectors. By utilizing connectors that are designed for easy disassembly, businesses can facilitate repairs and upgrades without the need for complete replacements. This not only conserves resources but also minimizes downtime, allowing for smoother operations and increased efficiency in the workplace.

Investing in well-maintained and adaptable connector systems can lead to substantial cost savings and improved operational reliability.