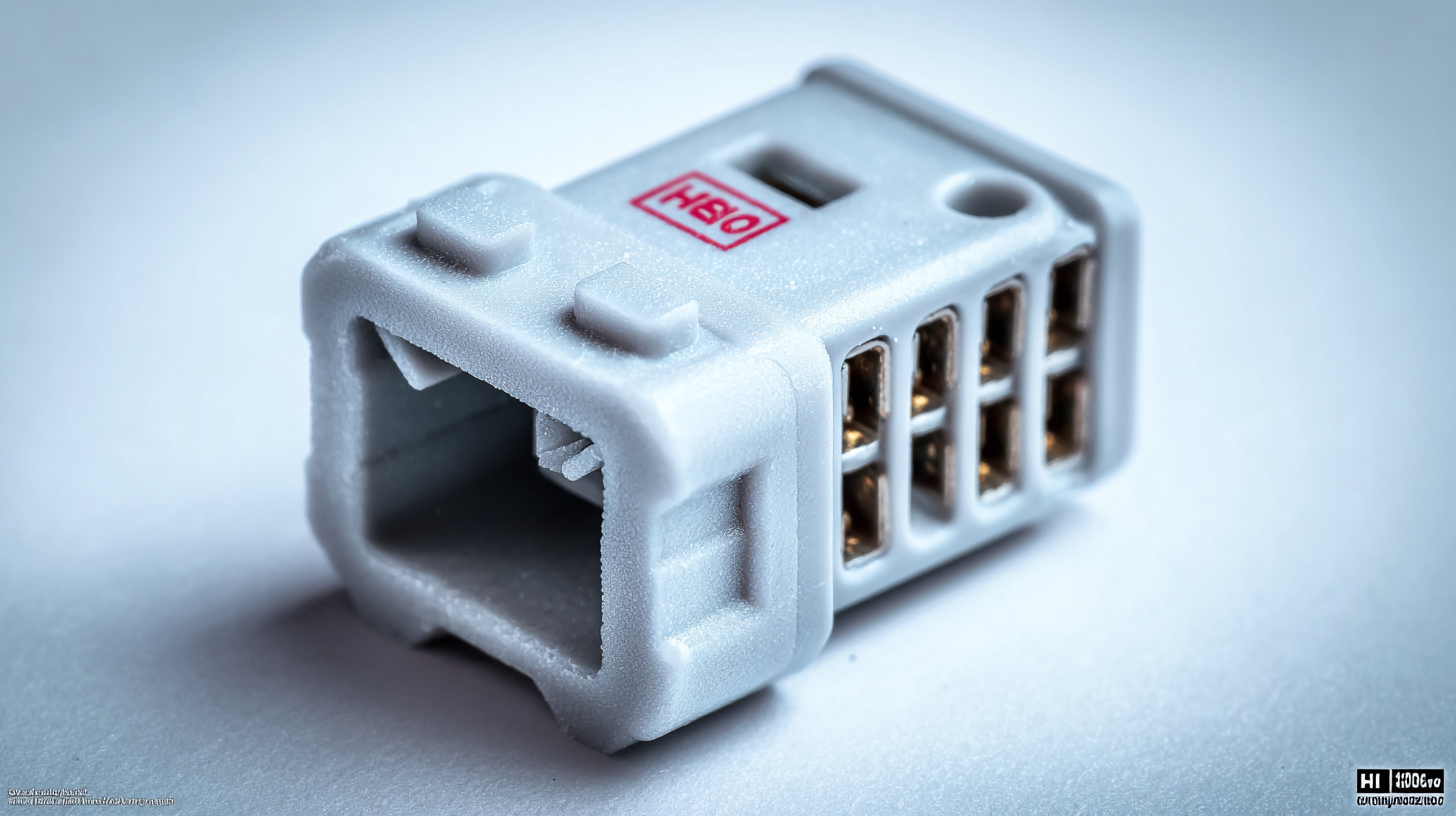

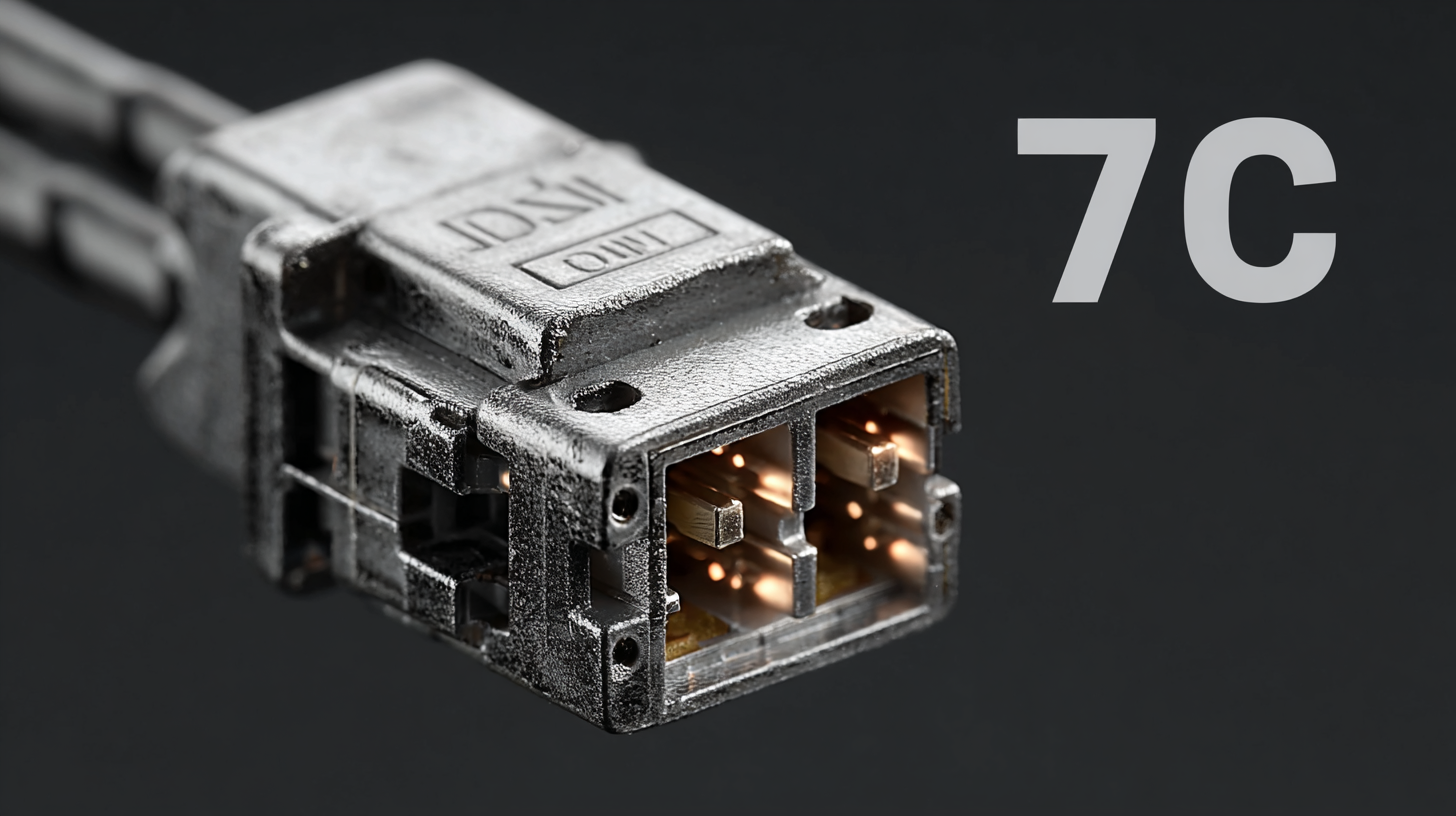

In today’s fast-paced and technologically advanced world, the selection of components for your projects can significantly influence their success. Among these components, the plastic rectangular connector stands out as an essential element that enhances both functionality and versatility. Sourced from China’s leading factories, these connectors are a testament to quality and reliability, garnering global trust among engineers and manufacturers alike. This blog delves into seven compelling reasons why incorporating the best plastic rectangular connector into your projects is not just beneficial, but necessary. From durability to ease of installation, the advantages these connectors offer can transform your approach to design and engineering, making them an indispensable part of your toolkit. Join us as we explore how the right plastic rectangular connector can elevate your projects to new heights, ensuring efficiency and excellence.

When selecting connectors for your projects, the importance of durability cannot be overstated.

Plastic rectangular connectors are integral to a wide range of applications, from consumer electronics to industrial systems. According to a study by MarketsandMarkets, the global plastic connectors market is projected to grow from $24.78 billion in 2020 to $38.77 billion by 2025, which underscores the increasing reliance on robust materials that can withstand environmental factors.

Durable connectors help ensure the longevity of your projects, as they are designed to resist moisture, dust, and chemical exposure.

Plastic rectangular connectors are integral to a wide range of applications, from consumer electronics to industrial systems. According to a study by MarketsandMarkets, the global plastic connectors market is projected to grow from $24.78 billion in 2020 to $38.77 billion by 2025, which underscores the increasing reliance on robust materials that can withstand environmental factors.

Durable connectors help ensure the longevity of your projects, as they are designed to resist moisture, dust, and chemical exposure.

Tip: When choosing a plastic rectangular connector, look for options that have been tested against standards such as UL 94 for flammability and IP ratings for ingress protection. These certifications are indicators of a connector's durability and reliability.

The right plastic rectangular connector not only enhances productivity but also minimizes downtime and maintenance costs. A report from Research and Markets highlights that using resilient connectors can reduce failure rates by up to 50% in harsh environments. Investing in durable connectors ultimately leads to higher efficiency and better performance for your projects.

Tip: Consider connectors that offer strain relief and innovative locking mechanisms. These features can substantially enhance durability, making sure that the connectors retain their reliability even in demanding scenarios.

When selecting the best plastic rectangular connectors for your projects, there are key features that significantly impact performance and reliability. One vital aspect is the connector's chemical resistance. According to a report by the Electronics Industry Association, connectors that withstand harsh chemicals are essential for applications in automotive and industrial sectors, where exposure to oils, fuels, and other fluids is common. High-quality plastic materials can provide improved durability and longevity, reducing the need for frequent replacements.

Another critical feature to consider is the environmental ratings, such as ingress protection (IP) ratings. A study published by the Institute of Electrical and Electronics Engineers (IEEE) highlights that connectors with higher IP ratings (like IP67 and above) are crucial for projects exposed to dust, moisture, and extreme temperatures. These ratings ensure that the connectors function reliably in demanding conditions, ultimately enhancing the performance of the entire electronic assembly. Additionally, the ability to support higher current and voltage ratings enables greater versatility and efficiency in diverse projects. By focusing on these essential features, you can ensure that the connectors you choose will meet the rigorous demands of your applications.

In today's rapidly evolving project environments, selecting the right components becomes crucial, especially when it comes to connectors. One significant aspect that often influences project success is cost-effectiveness. Investing in high-quality plastic rectangular connectors can yield substantial long-term savings by reducing the need for frequent replacements. While the initial outlay might seem higher, the durability and reliability offered by these connectors ensure that projects stay within budget over time, contributing to better resource allocation and enhanced overall performance.

Moreover, the trend toward integrating advanced wiring solutions further underscores the importance of choosing quality connectors. As the industry moves to streamline electrical assembly, effective connectors play a pivotal role in enhancing project efficiency. By preventing downtime caused by faulty connections, quality connectors support uninterrupted workflows, leading to reduced labor costs and increased productivity. This alignment of investment in robust connectors with overall project efficiency not only addresses immediate cost concerns but also lays a foundation for future scalability and innovation in project designs.

Plastic rectangular connectors are becoming increasingly popular in various industries due to their adaptability and reliable performance. These connectors can be found in a multitude of applications, from automotive to consumer electronics, owing to their unique ability to withstand environmental challenges such as moisture and temperature fluctuations. Their lightweight design not only simplifies the overall assembly process but also contributes to energy efficiency in electrical systems.

One of the standout features of plastic rectangular connectors is their modularity, which allows for easy customization and scalability across different projects. Whether you’re developing a sophisticated machinery control system or a compact handheld device, these connectors provide the flexibility needed to meet specific design requirements. In addition to their structural benefits, they often come with integrated features like locking mechanisms and strain reliefs, which enhance their durability and ease of use in demanding environments. This versatility makes plastic rectangular connectors an essential choice for professionals aiming for innovative and effective solutions in their projects.

In today's fast-paced construction and manufacturing industries, selecting high-quality connectors is crucial for enhancing project efficiency. The launch of advanced connectors, such as the recent Across crossWeb Connector, exemplifies the growing demand for seamless integration between systems, which streamlines project management through no-touch automation. As businesses transition towards digitization, the significant shift in workflow patterns underscores the necessity of utilizing reliable connector solutions that significantly reduce downtime and enhance productivity.

Data from the Heavy Duty Connector Market projects a remarkable growth, with an expected increase to USD 6.46 billion by 2034, indicating a compound annual growth rate (CAGR) of 5.48%. This surge reflects not only the expanding need for robust electrical connections in demanding environments but also the underlying trend of organizations prioritizing efficient project execution.

Furthermore, innovations like the latest SubConn connector, designed for optimal data integrity with minimized signal interference, highlight how technological advancements are pivotal in ensuring high-quality connectivity. Such enhancements are vital for teams in architecture, engineering, and construction (AEC), allowing them to leverage accurate data for informed decision-making and improved operational outcomes.