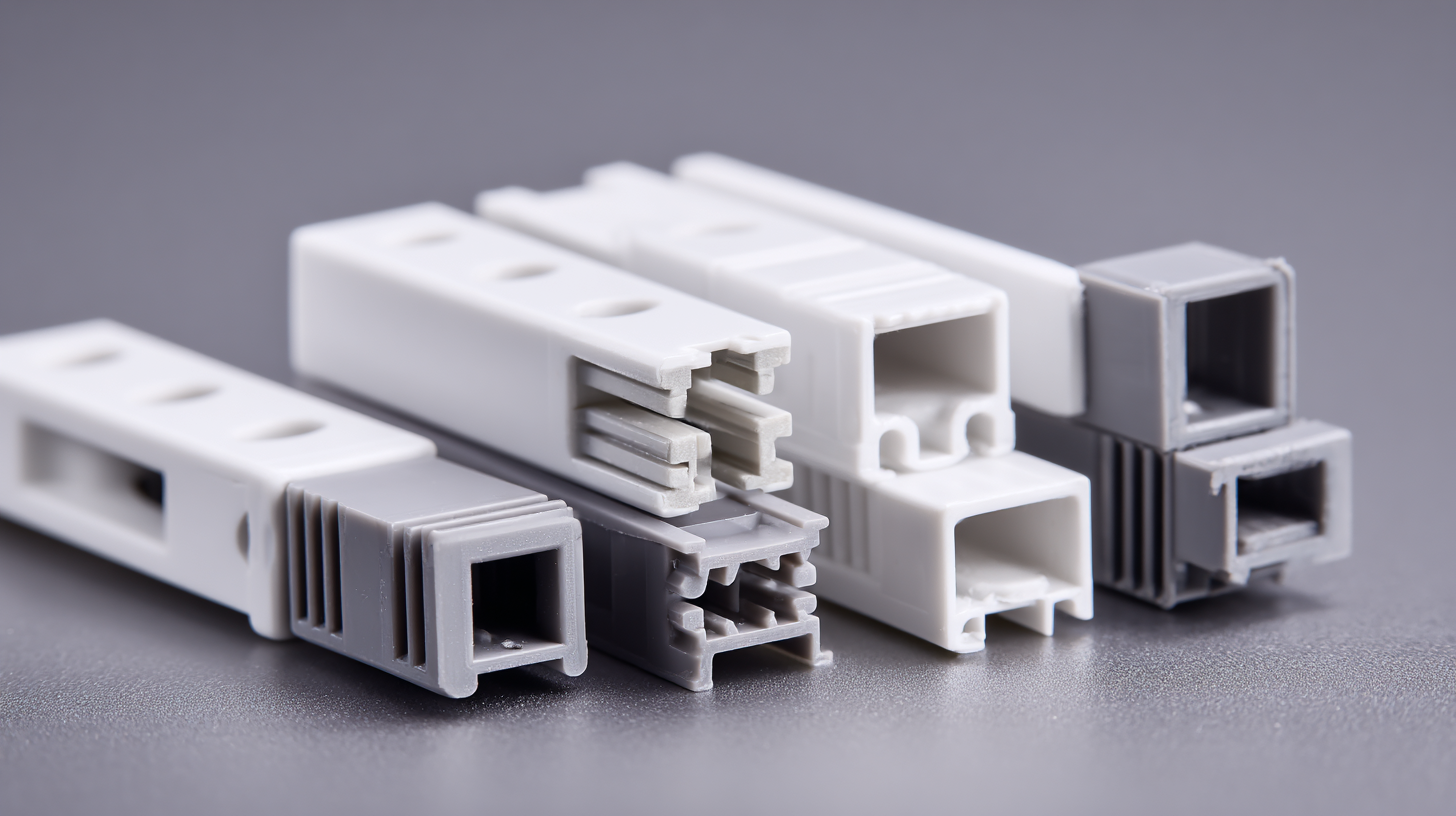

In today's interconnected world, where efficient supply chains are crucial for success, the role of plastic rectangular connectors cannot be overlooked. These innovative components serve as the backbone for numerous applications across various industries, offering durability, reliability, and versatility. As global suppliers seek to optimize their operations, understanding the benefits of plastic rectangular connectors becomes essential. From enhancing connectivity in electronic devices to facilitating seamless communication between different system components, these connectors play a vital role in driving productivity and innovation.

In this blog, we will explore seven compelling reasons why investing in the best plastic rectangular connectors is not only a smart choice but a necessary strategy for suppliers aiming to thrive in a competitive marketplace. Join us as we delve into the transformative impact of these connectors and uncover tips to maximize their potential.

As global supply chains continue to evolve, the demand for efficient and reliable components is at an all-time high. By 2025, plastic rectangular connectors are expected to play a pivotal role in meeting these demands due to their versatility and durability. Suppliers are increasingly recognizing the advantages these connectors offer, such as lightweight construction and resistance to environmental factors, which make them ideal for a variety of applications across different industries.

The shift towards sustainability in manufacturing practices is another driving force behind the rising popularity of plastic rectangular connectors. These connectors not only reduce the overall weight of products, thereby enhancing energy efficiency, but they also help lower costs associated with transportation and logistics. As companies strive to create more eco-friendly products, the incorporation of plastic connectors into supply chains represents a significant step towards achieving those sustainability goals. As the trend continues to gain momentum, suppliers will be better positioned to streamline operations and meet customer needs effectively.

In today's competitive manufacturing landscape, the significance of high-quality connectors cannot be underestimated. Industry statistics reveal that the global connectors market is projected to reach $107 billion by 2026, driven by the rising demand for efficient connectivity solutions in various sectors such as automotive, telecommunications, and consumer electronics. Reliable rectangular connectors are critical in ensuring seamless connections in electronic assemblies, directly impacting the overall performance and durability of products.

To maximize the effectiveness of these connectors, global suppliers should prioritize quality over cost. A recent study highlighted that nearly 40% of electronic failures can be attributed to poor connector integrity. Therefore, investing in the best plastic rectangular connectors can drastically reduce the risk of failures and enhance the longevity of products.

Tips: When selecting connectors, suppliers should consider environmental factors such as temperature and humidity, which can affect performance. Additionally, ensuring that connectors are tested in real-world conditions can provide valuable insights into their durability and reliability. With the right approach, companies can leverage high-quality connectors to maintain a competitive edge in the rapidly evolving market.

In the manufacturing sector, efficiency is key, and plastic rectangular connectors are revolutionizing how global suppliers streamline their operations. According to a recent report by MarketsandMarkets, the demand for connector technology is expected to grow at a CAGR of 6.3% from 2021 to 2026, reflecting the industry's shift towards lightweight and versatile solutions. Plastic rectangular connectors, known for their reliability and performance in various environments, are becoming integral to meeting these demands, especially in industries like automotive and consumer electronics.

One significant advantage of plastic rectangular connectors is their ability to reduce assembly time and costs. With their simple snap-in designs and versatile configurations, manufacturers can significantly minimize labor requirements. A study from Frost & Sullivan notes that companies that implement advanced connector solutions can achieve up to a 15% reduction in production line downtime. This improvement not only enhances overall output but also ensures that manufacturers maintain a competitive edge in a fast-paced market. As global suppliers continue to adapt to the evolving industrial landscape, the role of these innovative connectors will only grow more critical in enhancing manufacturing efficiency.

As global suppliers navigate the increasing pressure to adopt sustainable practices, the role of eco-friendly connectors becomes paramount. Plastic rectangular connectors, often overlooked for their functionality, can now be designed with sustainability in mind. These connectors can be manufactured from recyclable materials, minimizing their ecological footprint while maintaining performance and reliability.

When selecting connectors, suppliers should consider options that are not only made from sustainable materials but also promote efficiency in the assembly process. For instance, look for connectors that feature easy-to-use designs that reduce material waste during manufacturing. Incorporating modular designs can also enhance product longevity, allowing for easier repair and reduced waste.

Additionally, suppliers should seek out connectors that comply with international environmental standards. This effort not only meets regulatory requirements but also enhances the brand’s reputation among eco-conscious consumers. Engaging with manufacturers who prioritize sustainability can lead to innovative solutions that align with the profound trend towards a greener future.

| Reason | Description | Sustainability Impact |

|---|---|---|

| Durability | Plastic rectangular connectors offer high resistance to environmental factors. | Reduces waste and promotes longevity in supply chains. |

| Cost-Effectiveness | Lower production costs compared to metal counterparts. | Encourages economic sustainability for suppliers. |

| Lightweight Design | Easier to handle and reduce shipping costs. | Decreases carbon footprint during transportation. |

| Versatility | Applicable in various industries and environments. | Supports diverse eco-friendly applications. |

| Resistance to Corrosion | Ideal for harsh environments. | Less need for replacement, promoting resource conservation. |

| Recyclability | Can be recycled at the end of life, promoting circular economy. | Encourages sustainable disposal practices. |

| Innovation in Design | Continuous improvement in functionality and aesthetics. | Supports advancements in eco-friendly technology. |

The anticipated advances in plastic connector technology by 2025 are geared towards enhancing functionality and performance, making them indispensable for global suppliers. Recent developments in materials such as β-caryophyllene and PPS films indicate a trend towards using high-performance plastics in connector manufacturing. β-caryophyllene, with molecular formula C15H24, is said to possess unique properties that can be harnessed for creating innovative connector designs. With an increasing focus on lightweight and durable materials, these innovations promise to elevate the reliability and efficiency of plastic rectangular connectors.

Furthermore, the integration of advanced components like MT ferrules in MPO fiber optic connectors exemplifies the direction of future innovations. These structures facilitate precise alignment of multiple fibers, ensuring high-density connectivity and rapid data transmission capabilities. With anticipated market growth projected to reach several billion dollars in the coming years, suppliers are likely to leverage these advancements to meet the increasing demand for faster and more reliable connectivity solutions across various industries. The continual evolution of plastic connector technologies will play a critical role in shaping the future landscape of global supply chains.