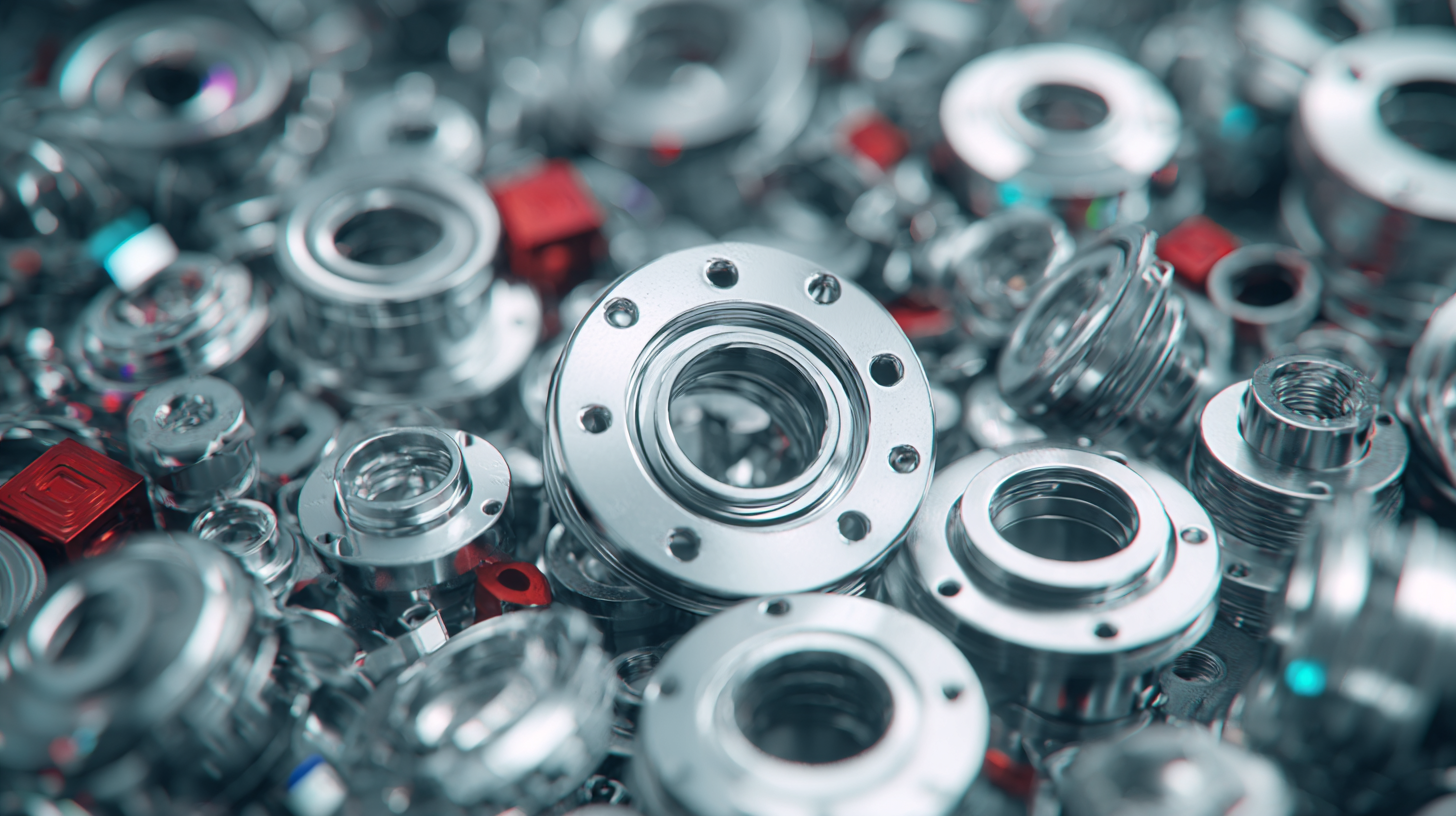

As the demand for reliable and efficient connectivity solutions continues to rise across various industries, metal circular connectors have emerged as a pivotal component in ensuring seamless communication and robust performance. According to a recent market research report by Fortune Business Insights, the global metal connector market is projected to grow at a compound annual growth rate (CAGR) of 5.8% from 2021 to 2028, highlighting the increasing reliance on these components in sectors such as aerospace, automotive, and telecommunications. In this context, China's commitment to quality assurance in the manufacturing of metal circular connectors has positioned it as a key player in the global marketplace. With advanced production techniques and rigorous testing protocols, Chinese manufacturers are not only meeting international standards but also setting new benchmarks for quality and innovation. This blog will explore the solutions provided by these manufacturers and how they contribute to ensuring global success in the connector industry.

The metal circular connector market is experiencing significant transformation, driven by technological advancements and increasing demand for high-quality connectivity solutions in various industries. By 2025, key trends such as miniaturization, enhanced durability, and the integration of smart technology will dominate the landscape. As manufacturers strive to meet these new requirements, the emphasis on quality assurance has never been more critical.

To ensure success in this competitive market, companies should prioritize rigorous testing and certification processes for their metal circular connectors. Implementing thorough quality checks during production can help in identifying potential failures early, thus ensuring reliability in real-world applications.

Additionally, fostering collaborative relationships with suppliers can enhance the overall quality of materials and components used in connector manufacturing. By sharing best practices and focusing on continuous improvement, manufacturers can better adapt to evolving market needs and maintain a strong position in the global marketplace. Embracing these trends and strategies will be vital for sustained growth and success in the metal circular connector sector by 2025.

In the competitive landscape of metal circular connectors, ensuring quality assurance is crucial for manufacturers aiming for global success. One effective strategy is implementing stringent testing protocols throughout the production process. Testing each batch with standardized methods helps identify and rectify potential issues before the connectors reach the market. This proactive approach not only enhances product reliability but also builds consumer trust.

Tip: Establish a dedicated quality assurance team that focuses solely on monitoring compliance with industry standards. This team should conduct regular audits and maintain comprehensive records of testing results to ensure consistent product performance.

Another key strategy is investing in advanced manufacturing technologies. By utilizing automation and precision engineering, manufacturers can enhance the consistency and quality of their products. The integration of smart technologies also enables real-time monitoring of the production line, allowing for quick adjustments when deviations occur.

Tip: Foster a culture of continuous improvement within the workforce. Encourage employees to report inefficiencies or defects, as their insights can lead to significant enhancements in production quality and operational effectiveness.

China has emerged as a dominant force in the global connector industry, primarily due to its robust manufacturing capabilities and commitment to quality assurance. The production of best metal circular connectors in China not only meets international standards but often exceeds them, giving Chinese manufacturers a significant competitive edge. This focus on quality ensures that products are reliable and durable, key attributes that global customers seek in connectors.

When looking to source connectors from China, here are a few tips to ensure you receive high-quality products. First, conduct thorough research on potential suppliers to assess their reputation and track record. Look for certifications such as ISO or UL, which indicate adherence to industry standards. Second, consider visiting manufacturing facilities if possible. This allows you to observe production processes and verify quality control measures firsthand. Lastly, establish clear communication with your supplier. Discuss expectations and quality requirements upfront to minimize misunderstandings.

As China continues to innovate and invest in advanced manufacturing technologies, its position in the global connector market is only expected to strengthen. This ongoing commitment to quality and efficiency will solidify China's reputation as a leader in the connector industry, providing customers worldwide with access to premium products.

When sourcing and manufacturing metal circular connectors, adhering to best practices is vital for ensuring quality and reliability. First and foremost, selecting reputable suppliers is crucial. Conducting thorough research and vetting potential partners will help identify manufacturers with a proven track record in quality assurance and consistent performance. Engaging with suppliers who invest in advanced technology and have established certifications can significantly enhance the overall production process.

Additionally, implementing strict quality control measures throughout the manufacturing cycle is essential. This includes regular inspections, testing for durability and performance, and using high-quality raw materials. Collaboration between engineers and quality assurance teams can facilitate the identification of potential issues early, enabling timely adjustments. Moreover, maintaining open communication with suppliers can foster a collaborative environment, where feedback is actively sought and implemented, ultimately leading to improved product outcomes and customer satisfaction.

The rapid evolution of technology significantly impacts the quality of metal circular connectors, propelling them to meet the demanding requirements of various industries. According to a recent report by MarketsandMarkets, the global connector market is projected to reach $96.8 billion by 2026, with a CAGR of 5.9%. This growth emphasizes the necessity for advanced manufacturing processes that enhance connector quality. Manufacturers in China are increasingly leveraging new technologies, such as automation and IoT, to achieve precision and reliability in their products.

Furthermore, the integration of smart manufacturing techniques has paved the way for innovative quality assurance practices. Real-time monitoring and performance analytics play a crucial role in identifying defects early in the production cycle. Data from the International Journal of Advanced Manufacturing Technology highlights that adopting these automated quality assurance systems can reduce production errors by up to 30%. As global competition intensifies, China's emphasis on technology-driven quality improvements in metal circular connectors positions it as a leader in the industry, fostering not only local success but also strong international partnerships.