News / Blog

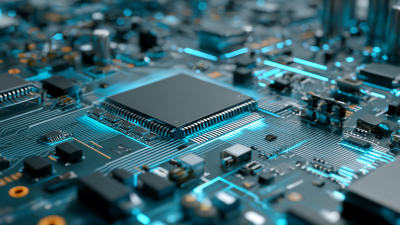

Why Electronic Capacitors Are Essential for Modern Electronics

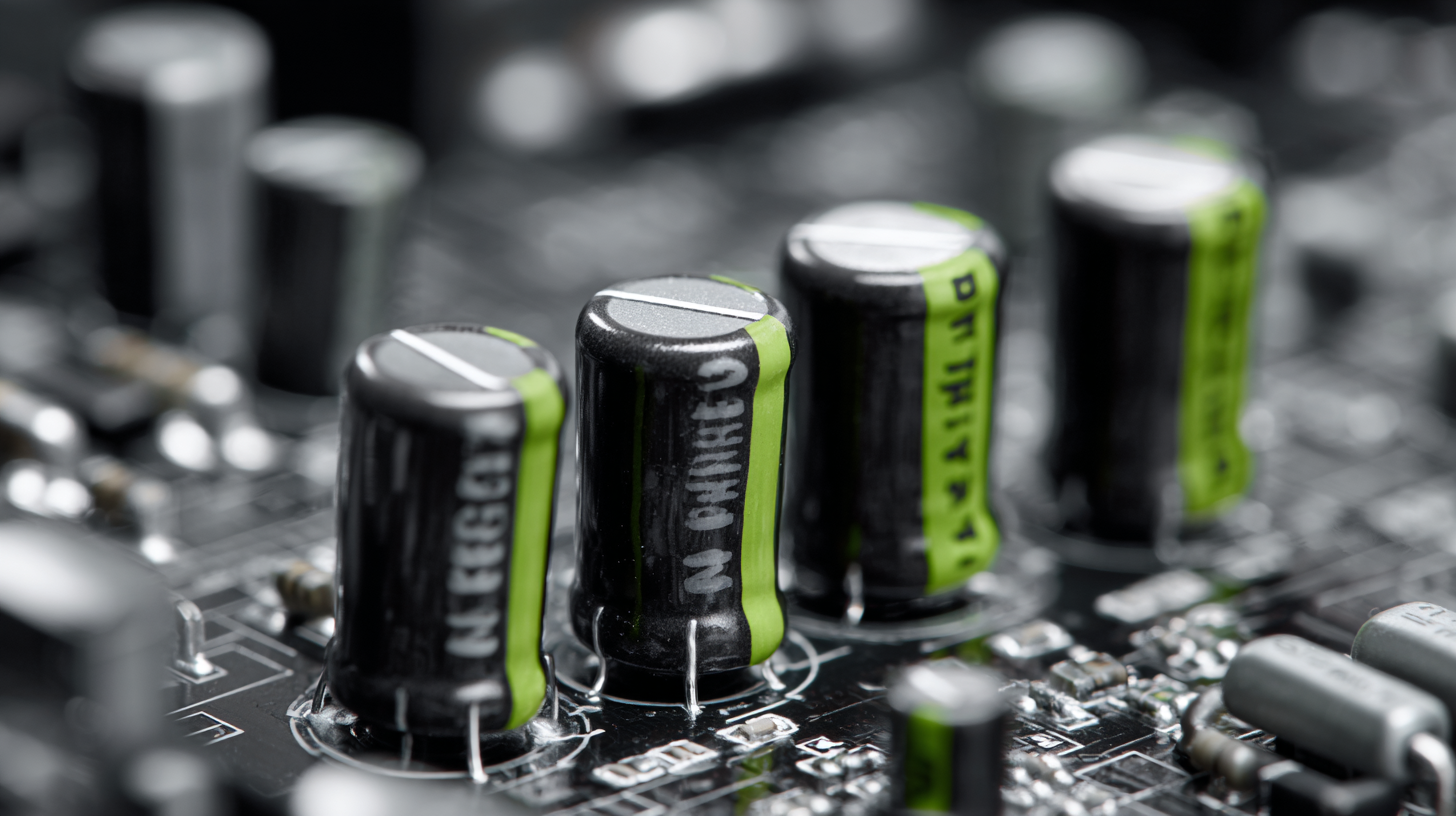

In the rapidly evolving world of modern electronics, electronic capacitors play a crucial role in ensuring the reliable operation of a wide array of devices. These essential components store and release electrical energy, enabling smooth functionality in everything from smartphones and computers to power supplies and automotive systems. With the increasing complexity of electronic circuits, the types of electronic capacitors, such as ceramic, electrolytic, and tantalum capacitors, each offer unique characteristics that cater to specific applications and requirements. Understanding the importance of electronic capacitors and their various types not only sheds light on their contribution to device performance but also highlights their significance in the advancement of technology. As we delve deeper into the world of electronic capacitors, we will explore their types, functions, and the pivotal role they play in shaping the future of electronics.

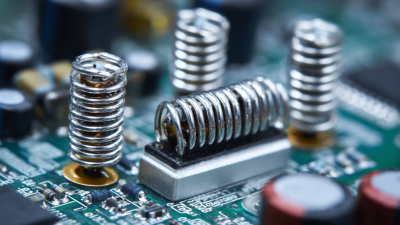

The Fundamental Role of Capacitors in Power Management Systems

In modern electronics, power management systems play a crucial role in ensuring devices operate efficiently and reliably. Capacitors are integral to these systems, providing essential functions such as energy storage, filtering, and voltage regulation. By storing electrical energy temporarily, capacitors help smooth out fluctuations in power supply, which is vital for maintaining stable operation in sensitive electronic components.

Furthermore, capacitors enhance the performance of power converters and regulators by minimizing ripple voltage and ensuring steady output levels. This is particularly important in applications such as renewable energy systems, where the variability of power sources requires robust management strategies.

The ability of capacitors to quickly charge and discharge makes them indispensable in maintaining the efficiency and longevity of modern electronic devices, ultimately contributing to better performance and reduced energy wastage in power management systems.

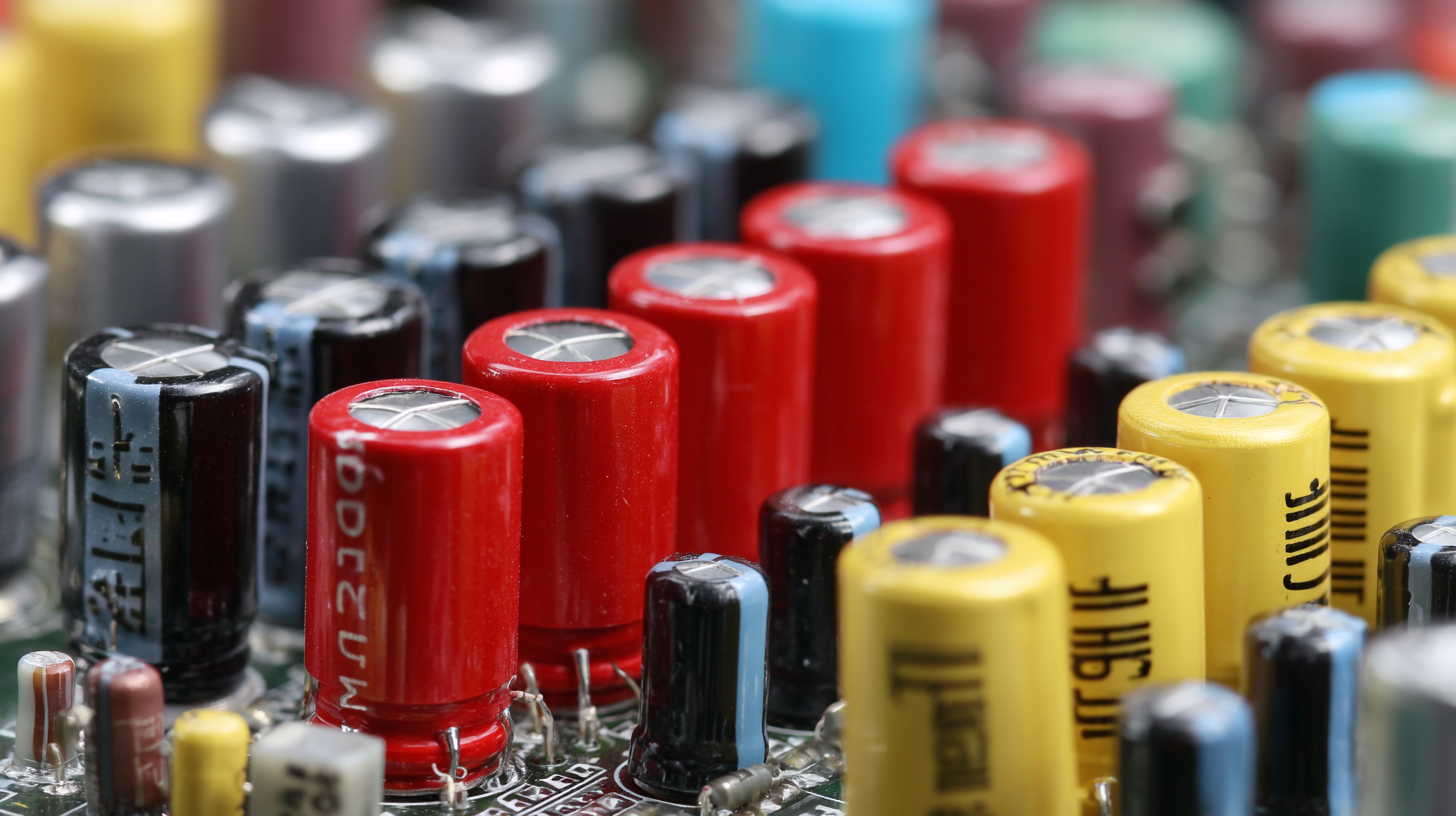

Impact of Capacitor Quality on Circuit Efficiency and Performance

The quality of electronic capacitors significantly influences the efficiency and performance of modern circuits. High-quality capacitors are essential for maintaining stable voltage levels and reducing ripple in power supply circuits. When capacitors possess low equivalent series resistance (ESR), they allow for fast charge and discharge cycles, which are vital for applications such as signal processing and energy storage. Poor-quality capacitors, on the other hand, can lead to voltage drops, increased heat generation, and ultimately reduced circuit reliability.

Moreover, the choice of capacitor materials directly affects their longevity and operational stability. Capacitors constructed from high-grade materials exhibit greater tolerance to temperature fluctuations and electrical stress, which enhances their lifespan and overall system performance. In high-frequency applications, such as RF circuits, the use of well-engineered capacitors is crucial to prevent signal degradation and maintain communication fidelity. As consumer demand for more efficient and compact electronic devices grows, the role of superior capacitors becomes increasingly central, connecting the dots between design innovation and practical functionality in modern electronics.

Why Electronic Capacitors Are Essential for Modern Electronics

This bar chart illustrates the impact of capacitor quality on circuit efficiency and performance across different applications in modern electronics, showcasing the relative performance of various types of capacitors.

Global Market Trends: The Growing Demand for Advanced Electronic Capacitors

The global market for electronic capacitors is witnessing a remarkable surge, driven by the escalating demand for advanced technologies in various sectors, including automotive and industrial applications. Projections indicate that the power electronics market size will grow from $25.78 billion in 2024 to $43.42 billion by 2032, boasting a compound annual growth rate (CAGR) of 6.7%. As industries increasingly adopt innovative electronic solutions, the need for efficient and reliable electronic capacitors becomes imperative.

For professionals in the electronics industry, it’s crucial to stay updated on market trends. Tip: To enhance your product offerings, consider investing in advanced capacitor technologies such as multilayer ceramic capacitors (MLCC) or hybrid capacitors, which are poised for significant growth. The hybrid capacitor market alone is expected to exceed $570 million in 2024, with a CAGR of 20.5% until 2034, primarily fueled by the rising demand for electric and hybrid vehicles.

Furthermore, the atomic layer deposition (ALD) market is projected to experience substantial growth, anticipated to increase from $252.74 million in 2025 to $1.462 billion by 2033. Tip: Companies should explore partnerships with ALD technology providers to leverage cutting-edge manufacturing techniques in their capacitor production to meet evolving market demands and ensure a competitive edge. As the landscape of electronic capacitors continues to evolve, remaining agile and informed will be key to success in this burgeoning market.

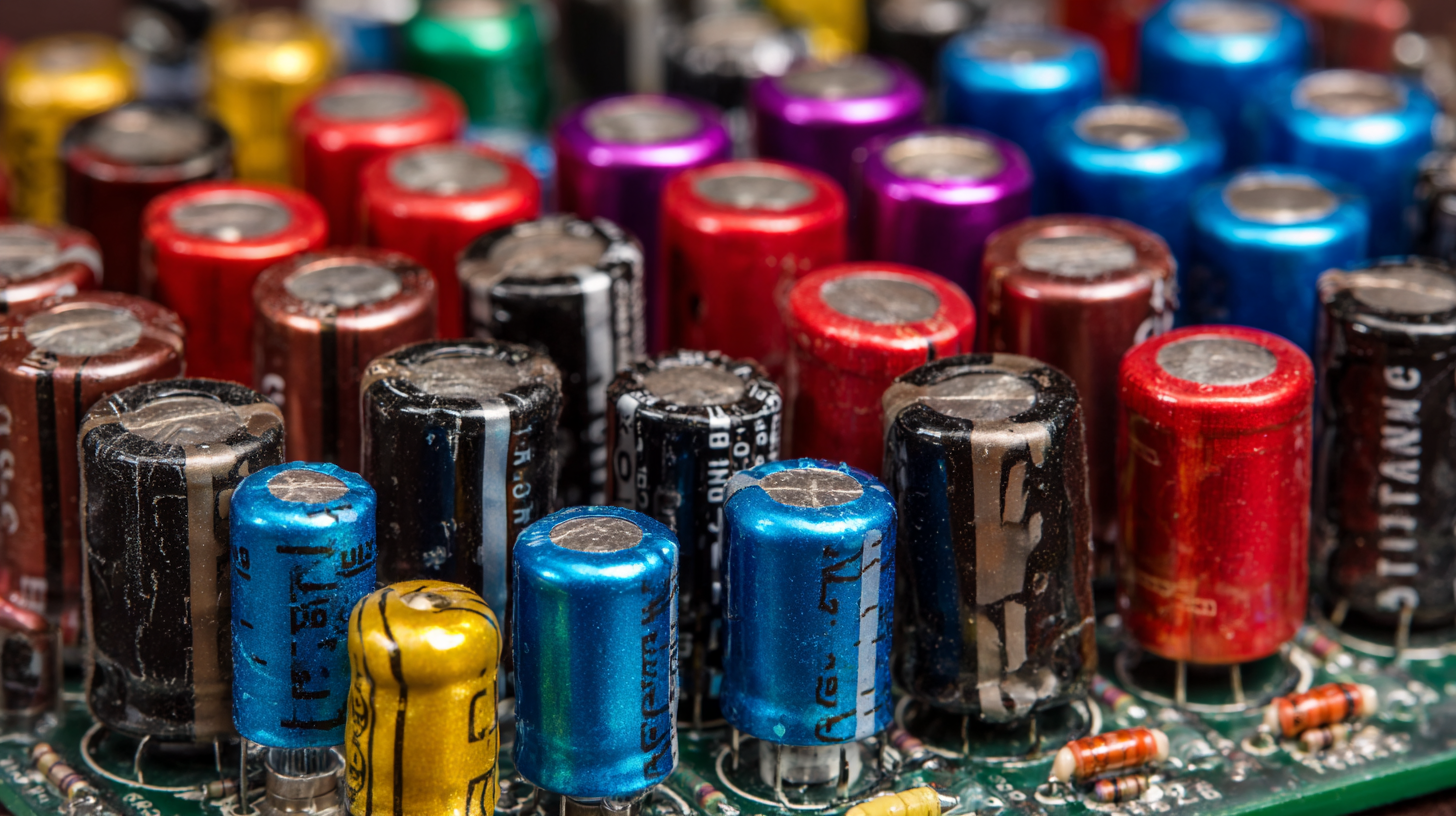

Innovations in Capacitor Technology: Enhancing Reliability and Longevity

Innovations in capacitor technology are transforming the landscape of modern electronics, offering enhanced reliability and longevity crucial for various applications. As the demand for efficient energy storage solutions grows, advancements in materials and design are paving the way for next-generation capacitors. For instance, nanostructured plastics are being utilized to improve the performance of high-voltage capacitors, significantly extending their lifespan. These innovations are essential as the industry moves towards more sustainable energy systems and strives to achieve net-zero carbon footprints.

In the realm of electric vehicle (EV) technology, improved capacitor systems are integral to advanced battery management systems (BMS). Research highlights the importance of capacitors in optimizing energy flow, ensuring safety, and enhancing the overall efficiency of electric powertrains. With developments focusing on supercapacitors, which promise faster charging times and longer lifecycle compared to traditional batteries, manufacturers are better equipped to meet the increasing energy demands of next-generation electronic devices. This synergy between capacitor technology and energy storage solutions underscores the critical role capacitors play in the ongoing evolution of modern electronics.

Environmental Considerations: The Shift Towards Eco-Friendly Capacitor Designs

The growing awareness of environmental issues has prompted significant changes in the design and production of electronic capacitors. Traditionally, many capacitors contained hazardous materials that posed risks during manufacturing, usage, and disposal. However, recent innovations focus on eco-friendly designs that reduce these environmental impacts. Manufacturers are increasingly substituting harmful substances with sustainable alternatives, fostering a safer ecosystem and extending the life cycle of products.

Moreover, the shift toward eco-friendly capacitor designs is not only beneficial for the environment but also aligns with evolving consumer preferences. As eco-consciousness rises, consumers are now more inclined to choose products that prioritize sustainability. This creates a market demand for capacitors made from recyclable materials and those that comply with environmental regulations. As a result, companies are investing in research and development to create capacitors that maintain high performance while minimizing their ecological footprint. Such advancements signify a collective effort to harmonize technological progress with environmental responsibility in the electronics industry.