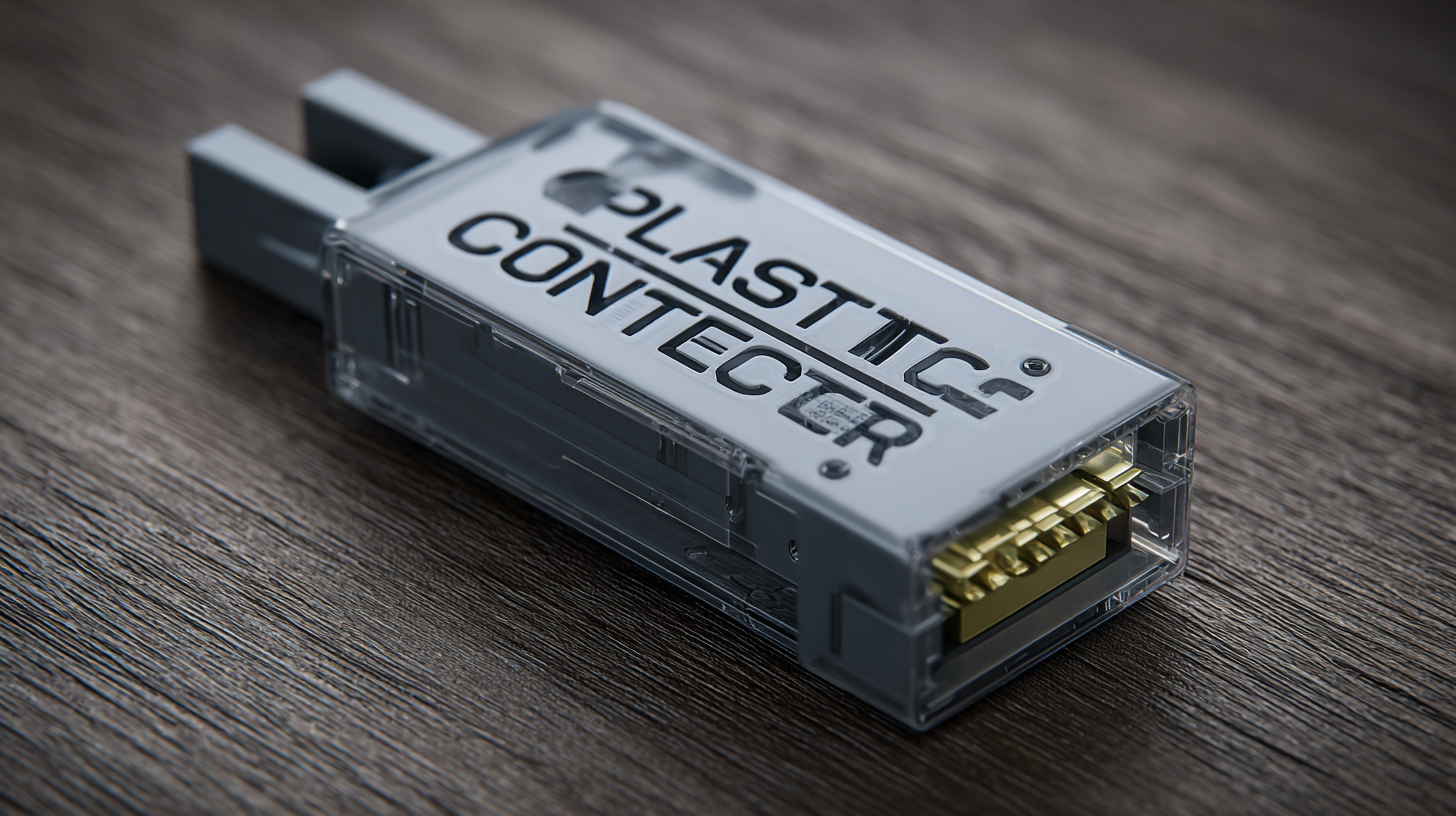

As we look toward 2025, the demand for plastic rectangular connectors is projected to grow exponentially, driven by advancements in technology and the increasing prevalence of electronic devices across various industries. According to a recent market analysis by Research and Markets, the global connectors market is expected to reach USD 90 billion by 2025, with plastic connectors capturing a significant portion due to their lightweight, cost-effective, and versatile nature.

As we look toward 2025, the demand for plastic rectangular connectors is projected to grow exponentially, driven by advancements in technology and the increasing prevalence of electronic devices across various industries. According to a recent market analysis by Research and Markets, the global connectors market is expected to reach USD 90 billion by 2025, with plastic connectors capturing a significant portion due to their lightweight, cost-effective, and versatile nature.

In particular, plastic rectangular connectors are noted for their robust performance in harsh environments, further enhancing their appeal in sectors such as automotive, telecommunications, and consumer electronics. This blog explores the innovative alternatives and advancements in the manufacturing processes of these connectors, spotlighting leading factories in China that are setting benchmarks for quality and efficiency, ultimately reshaping the landscape of electronic connectivity.

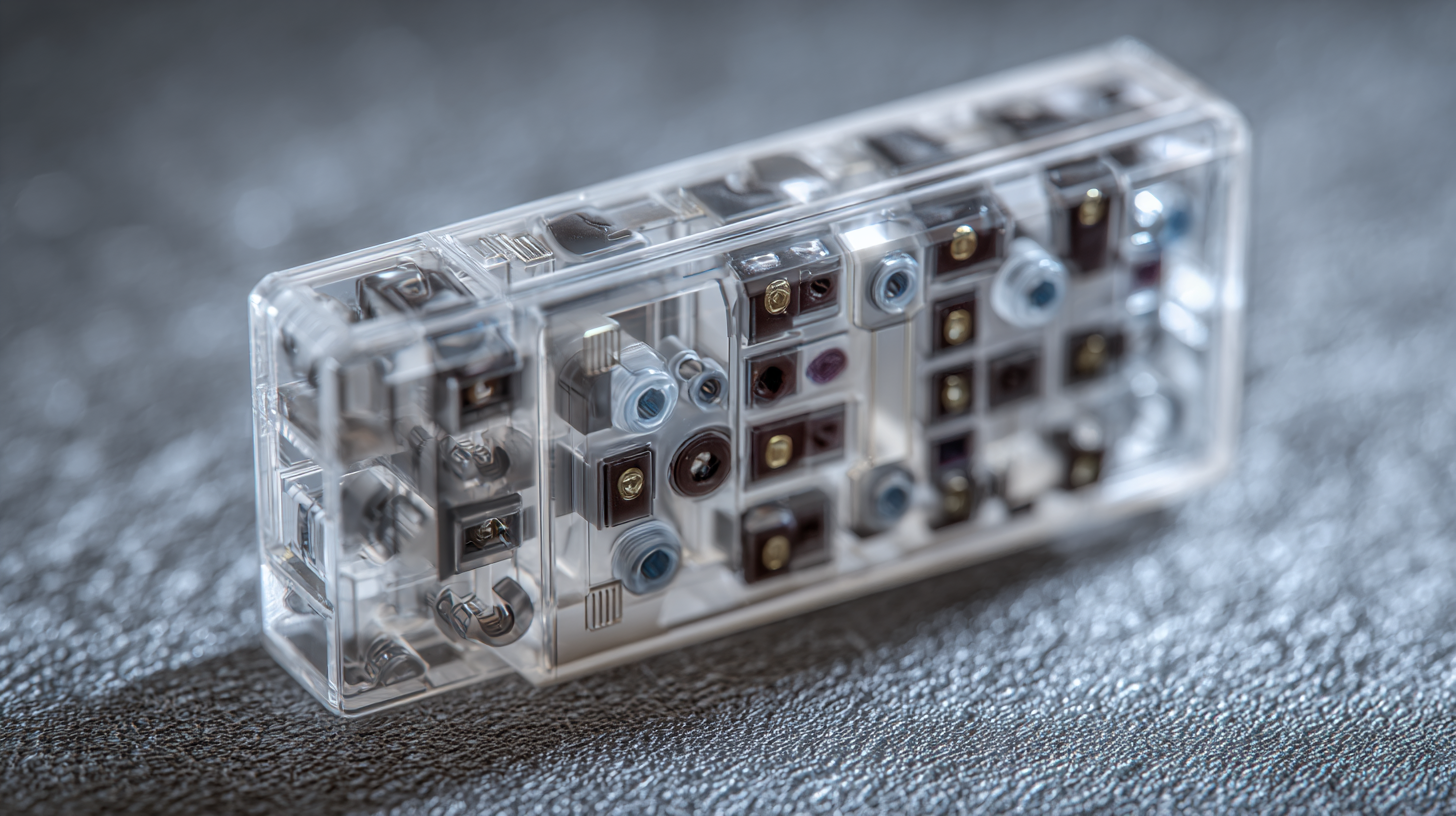

As we look ahead to 2025, the landscape of plastic rectangular connectors is set for significant transformation driven by advancements in material science and manufacturing techniques. One of the key trends is the growing demand for connectors that offer enhanced durability and resistance to environmental factors. Manufacturers are likely to explore innovative materials, such as bio-based plastics and composites, which provide not only sustainability but also superior electrical performance. This shift will cater to industries ranging from automotive to consumer electronics, where reliability is paramount.

Another trend to anticipate is the integration of smart technology into plastic connectors. With the rise of the Internet of Things (IoT), connectors that can communicate data and monitor performance are becoming increasingly essential. By incorporating smart sensors into rectangular connectors, manufacturers can create solutions that allow for real-time assessments of electrical connections, thus improving safety and efficiency. This evolution towards smart connectors will revolutionize how we interact with electrical systems and pave the way for a more interconnected future.

The plastic connector industry is witnessing significant transformations driven by advancements in materials and technologies. With the global thermoplastic polyester elastomers (TPEE) market projected to reach $1.41 billion by 2025 and to grow at a compounded annual growth rate (CAGR) of 6.8%, it underscores a growing demand for innovative plastic solutions. The integration of laser plastic welding technology is paving the way for advancements in thermal management systems, particularly in electric vehicles (EVs), which are reliant on efficient heat dissipation strategies. Effective thermal management directly enhances battery performance, lifespan, and safety, making it a critical design consideration in EV manufacturing.

Additionally, the engineering plastics market, expected to expand significantly, showcases a range of materials such as polyamide (PA), polycarbonate (PC), and polypropylene (PP), vital for various applications across industries. As the demand for medical-grade plastics increases, owing to their superior sterilization and safety properties compared to traditional materials, manufacturers are shifting focus toward these high-performance alternatives. The insights from recent reports reflect an evolving landscape, where innovation in connector technology and material science will shape the future of manufacturing and design in the years to come.

| Connector Type | Material | Max Operating Temperature (°C) | IP Rating | Current Rating (A) | Recyclability |

|---|---|---|---|---|---|

| Standard Rectangular Connector | Polycarbonate | 85 | IP67 | 20 | Yes |

| High-Temperature Connector | Liquid Crystal Polymer | 150 | IP66 | 10 | Yes |

| Waterproof Connector | Nylon | 90 | IP68 | 15 | Yes |

| Eco-Friendly Connector | Biodegradable Plastic | 80 | IP65 | 12 | Yes |

As we venture into 2025, the demand for plastic rectangular connectors continues to rise, prompting a closer look at their performance compared to innovative alternatives. Plastic connectors are favored for their lightweight characteristics, versatility, and cost-effectiveness; however, concerns regarding durability and environmental impact have led industry experts to explore new materials. Metals such as aluminum and various composites are emerging as strong contenders, offering enhanced strength and longevity.

In recent analyses, alternative materials have been observed for their ability to withstand harsher environments, making them suitable for industries that require robust solutions. For instance, thermoplastics reinforced with fiberglass or carbon fibers demonstrate superior mechanical properties, allowing for greater resilience without excessive weight. Additionally, bioplastics are gaining traction as sustainable alternatives, appealing to eco-conscious consumers and businesses alike. The comparative performance of these materials against traditional plastic connectors will play a vital role in shaping the future landscape of connectivity solutions.

As the demand for sustainable materials continues to rise, the connector manufacturing industry is embracing eco-friendly plastics as a vital component in the design of rectangular connectors. These innovative materials not only reduce environmental impact but also enhance the durability and performance of the final products. In 2025, we expect to see a significant shift towards bioplastics and recycled plastics, which offer the necessary strength and flexibility required for connectors while being more responsibly sourced.

The integration of sustainability into connector design extends beyond material selection. Manufacturers are rethinking production processes, aiming to reduce waste and energy consumption. By adopting practices such as injection molding with sustainable polymers and optimizing the design for recyclability, the industry can significantly lower its carbon footprint. As consumers increasingly prioritize eco-friendly options, manufacturers are seizing the opportunity to differentiate themselves through sustainable innovation, paving the way for a cleaner, greener future in connector technology.

As we look into the future of plastic rectangular connectors, it is evident that innovation is at the forefront of industry advancements. New materials and manufacturing techniques promise to enhance the durability and functionality of these essential components. For instance, the introduction of advanced polymer composites is geared towards improving strength while reducing weight, making connectors more efficient in various applications, from automotive to consumer electronics.

Additionally, the integration of smart technology into connector designs is set to revolutionize connectivity. Features such as built-in sensors for real-time performance monitoring will offer unprecedented reliability and ease of maintenance.

Moreover, the push for sustainability is driving the development of eco-friendly alternatives in connector solutions. Companies are exploring bioplastics and recyclable materials that align with global environmental goals. This not only meets the increasing demand for sustainable products but also opens doors to innovative designs that can adapt to renewable energy systems and smart grids.

As we advance towards 2025, these enhancements will reshape the connectivity landscape, catering to the evolving needs of industries while emphasizing innovation and sustainability.