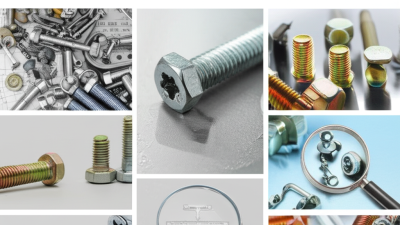

In the fast-paced world of manufacturing and construction, selecting the right joint fasteners is crucial for ensuring structural integrity and operational efficiency. According to a recent market report by Grand View Research, the global fasteners market is expected to reach USD 113.8 billion by 2027, driven by increasing demand across various industries, including automotive, aerospace, and construction. As businesses strive for excellence, mastering global standards for joint fasteners becomes essential for maintaining quality and safety.

This blog will delve into how to identify and choose high-quality joint fasteners from reputable manufacturers, ensuring that your projects meet both performance specifications and regulatory requirements. Understanding the nuances of joint fasteners and their applications can significantly impact your project's success and longevity.

Global standards in fasteners play a crucial role in ensuring safety, functionality, and compatibility across various industries. These standards, set by organizations such as ASTM International and ISO, provide guidelines that manufacturers must follow to produce reliable and consistent products. By adhering to these regulations, companies can reduce the risk of failures in applications where fasteners are critical, such as in construction, automotive, and aerospace sectors. The uniformity created by these standards not only fosters trust among consumers but also simplifies the procurement process by enabling easier comparisons among different suppliers.

Moreover, understanding global standards aids businesses in making informed decisions when selecting fasteners for specific applications. Whether a company is sourcing bolts, nuts, screws, or washers, knowing the specifications required for their unique needs ensures they choose the right products. Compliance with these standards often means that fasteners are tested for quality and durability, making them suitable for demanding environments. Thus, emphasizing the importance of global standards doesn't just protect the integrity of a project; it also enhances overall efficiency and reduces long-term costs associated with failures or replacements.

When selecting joint fasteners, understanding the key types and their applications is crucial to ensure durable and effective connections. Composite materials, for instance, exhibit unique failure modes, including net-tension, shear-out, and bearing modes. Each of these failure modes highlights different ways a joint can fail under load, which can greatly influence the choice of fastener used in the application. According to the American Society for Testing and Materials (ASTM), the optimal fasteners for composites often include those made from high-strength materials that can mitigate the risk associated with these failure modes.

Net-tension failure typically occurs when tensile loads exceed the material's strength, making it essential to select fasteners that distribute loads evenly. In contrast, shear-out failures arise when shear forces exceed component shear capacity, suggesting that fasteners should be strategically placed to maximize the load-bearing capacity. Lastly, bearing modes dictate that the fastener's bearing area must be sufficient to resist the applied loads without crushing the composite material. Research indicates that the use of oversized holes and controlled torque can further enhance the performance of joint fasteners in composite applications, ensuring optimal reliability and longevity of the assembly.

When selecting the right joint fasteners for your projects, several critical factors come into play. First, understanding the material compatibility is essential. According to a report by the Institute of Industrial Engineers, approximately 30% of fastening failures arise from material incompatibility. Choosing fasteners made from materials that can withstand the specific environmental conditions—such as corrosion, temperature fluctuations, and mechanical stress—is vital for ensuring long-term durability.

Another important consideration is the fastener's size and strength. Research indicates that fasteners that do not meet the required mechanical specifications contribute to nearly 25% of assembly defects. It is crucial to ensure that the selected fasteners align with both the load requirements and the specifications outlined in industry standards, such as ASTM and ISO. Additionally, when evaluating the production techniques, reports highlight that fasteners produced through advanced technologies, like cold heading and precision machining, offer enhanced performance and reliability, minimizing the risk of failure in demanding applications.

| Fastener Type | Material | Corrosion Resistance | Strength Rating | Application |

|---|---|---|---|---|

| Bolt | Steel | Moderate | Grade 8 | Heavy Machinery |

| Screw | Stainless Steel | High | Grade A | Outdoor Furniture |

| Nail | Galvanized Steel | Moderate | N/A | Construction |

| Anchor | Zinc Alloy | High | Heavy Duty | Concrete Structures |

| Washer | Plastic | High | N/A | Electrical Applications |

When selecting joint fasteners, the choice of material is crucial as it directly impacts strength, durability, and resistance to environmental factors. Common materials include steel, aluminum, and plastic, each with its own advantages and drawbacks. Steel fasteners are renowned for their strength and load-bearing capabilities, making them ideal for heavy-duty applications. However, their susceptibility to rust and corrosion necessitates appropriate coatings or treatments, especially in humid or corrosive environments.

Aluminum fasteners, on the other hand, offer a lightweight alternative that provides good corrosion resistance. They are often used in applications where weight savings are paramount, such as in aerospace industries. Yet, while aluminum is less prone to rust, it may not withstand high-stress loads as effectively as steel, which can be a limitation in certain scenarios. In contrast, plastic fasteners are suitable for applications requiring electrical insulation and resistance to chemical exposure, but they typically lack the strength of metal options. Understanding these material characteristics helps in making informed decisions when choosing the right joint fasteners for your specific needs.

When it comes to ensuring the quality and reliability of joint fasteners, adherence to best practices is essential. First and foremost, it is crucial to understand the specific requirements of your application. This involves evaluating factors such as load capacity, environmental conditions, and material compatibility. Selecting fasteners that are engineered for these specifications not only enhances performance but also promotes safety in operation.

Another vital practice is to inspect and certify fasteners through recognized industry standards. This ensures that each component meets stringent quality criteria. Look for fasteners that have been tested under various conditions and possess certifications from reputable organizations.

Additionally, sourcing materials from trusted suppliers who comply with global standards can minimize the risks associated with low-quality fasteners. Regular training and updates on industry advancements for your team can also contribute significantly to maintaining a high level of quality control in your fastener selection process.

By focusing on these best practices, you can significantly enhance the reliability of your fastening solutions.