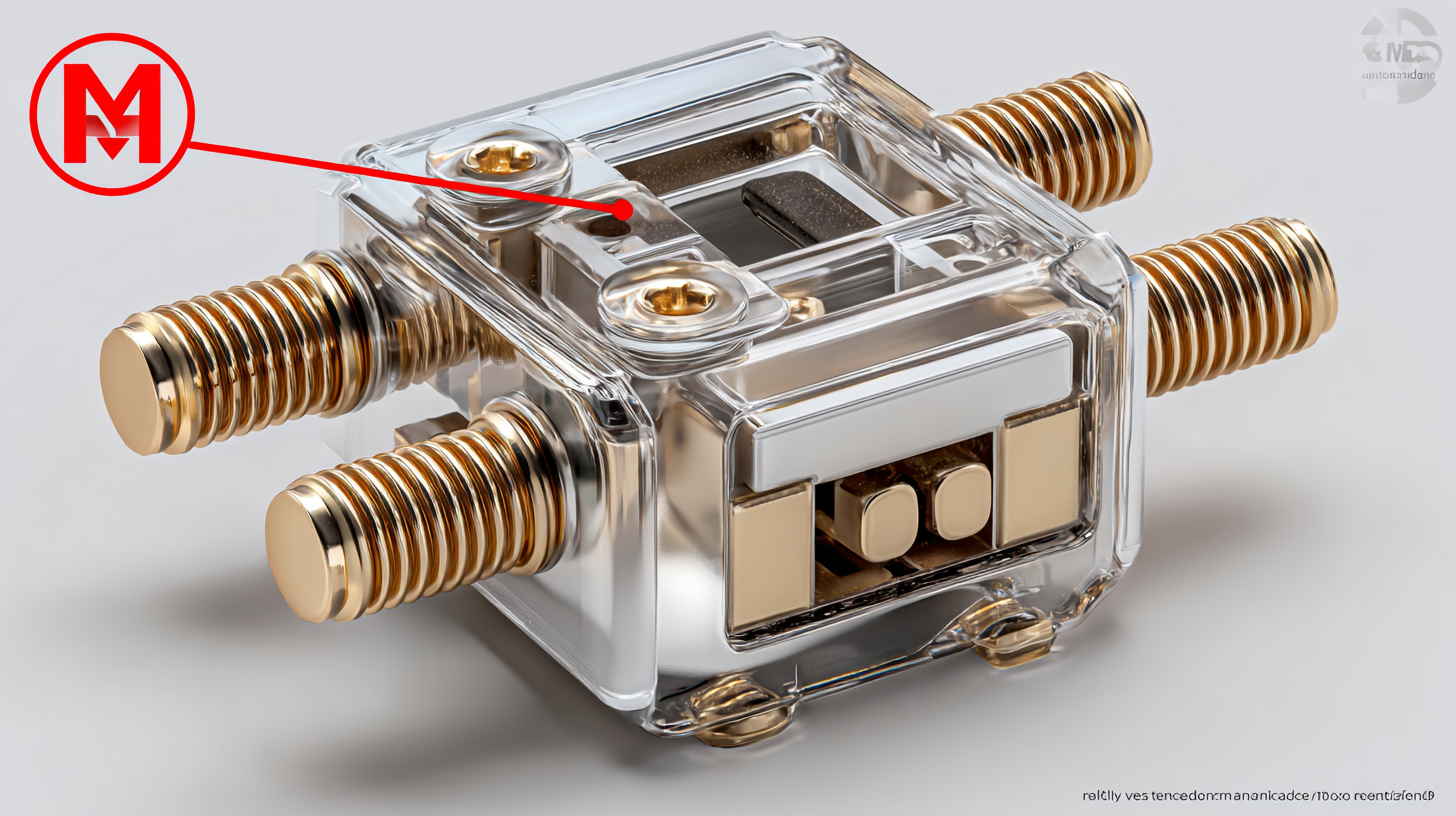

In the competitive landscape of electronic components, maximizing value from after-sales services is essential, especially concerning Rectangular connectors. According to a recent industry report by Market Research Future, the global connector market is projected to reach USD 85 billion by 2027, with Rectangular connectors playing a pivotal role due to their versatility and efficiency in various applications.

With rising manufacturing costs, minimizing repair expenses has become a strategic priority for companies. Implementing effective after-sales service techniques not only enhances customer satisfaction but can significantly reduce long-term operational costs. As organizations navigate the complexities of connector technologies, focusing on after-sales strategies is fundamental to sustaining profitability and fostering customer loyalty in an ever-expanding market.

When it comes to ensuring the longevity of rectangular connectors, effective after-sales support is crucial. One key strategy is to provide comprehensive training for users, enabling them to understand proper installation and maintenance techniques. This not only reduces the likelihood of misuse but also enhances the performance of the connectors over time.

Another important aspect is to establish a clear communication channel for customers. Being responsive to inquiries and feedback allows manufacturers to address potential issues before they escalate into costly repairs. Regular follow-ups can help in identifying early signs of wear or malfunction, ensuring timely interventions.

Additionally, offering extended warranties or service plans can give users peace of mind and encourage them to maintain their connectors properly. Regular check-ups and maintenance services can significantly reduce repair costs, allowing customers to maximize the value of their investment and extend the lifespan of their rectangular connectors.

This bar chart illustrates the average repair costs associated with different after-sales service strategies for rectangular connectors. The data highlights the importance of proactive maintenance, warranty services, and customer support in minimizing repair expenses.

Understanding the cost implications of after-sales services is crucial for ensuring optimal performance and longevity of the best rectangular connectors. By investing in proper service practices, users can significantly reduce repair costs, which often arise from neglect or inadequate maintenance.

One effective tip is to schedule regular inspections, as these can identify potential issues before they escalate, saving both time and money in the long run.

Another essential aspect is to maintain clear communication with your supplier regarding warranty services. Knowing the specifics of what’s covered can prevent unexpected expenses and ensure that any necessary repairs utilize the best available resources.

Additionally, training your staff on proper handling and installation techniques is invaluable. Educated personnel are less likely to cause damage that leads to costly repairs, thereby maximizing the value of your connector investment.

Proper maintenance practices are essential for maximizing the value and longevity of rectangular connectors, much like the preventative measures important in the automotive industry. Just as regular vehicle checks can significantly reduce the likelihood of breakdowns, routine maintenance of electrical connections in connectors can prevent costly repairs. According to a report by the Electrical Connector Industry Association, approximately 40% of connector failures are attributed to poor maintenance and corrosion. Implementing effective cleaning techniques and using corrosion-resistant materials can extend the lifespan of connectors.

Moreover, the trend toward preventative maintenance mirrors successful strategies in various sectors. For instance, refuse truck operators have reported that a regular maintenance schedule can cut repair costs by up to 30%, highlighting the critical role of consistent upkeep in maintaining operational efficiency. Similarly, for rectangular connectors, establishing a routine inspection and maintenance program can minimize faults and ensure a reliable connection, ultimately reducing repair needs and costs. It is evident that adopting best practices in maintenance is not just beneficial but crucial for optimizing the performance of electrical components.

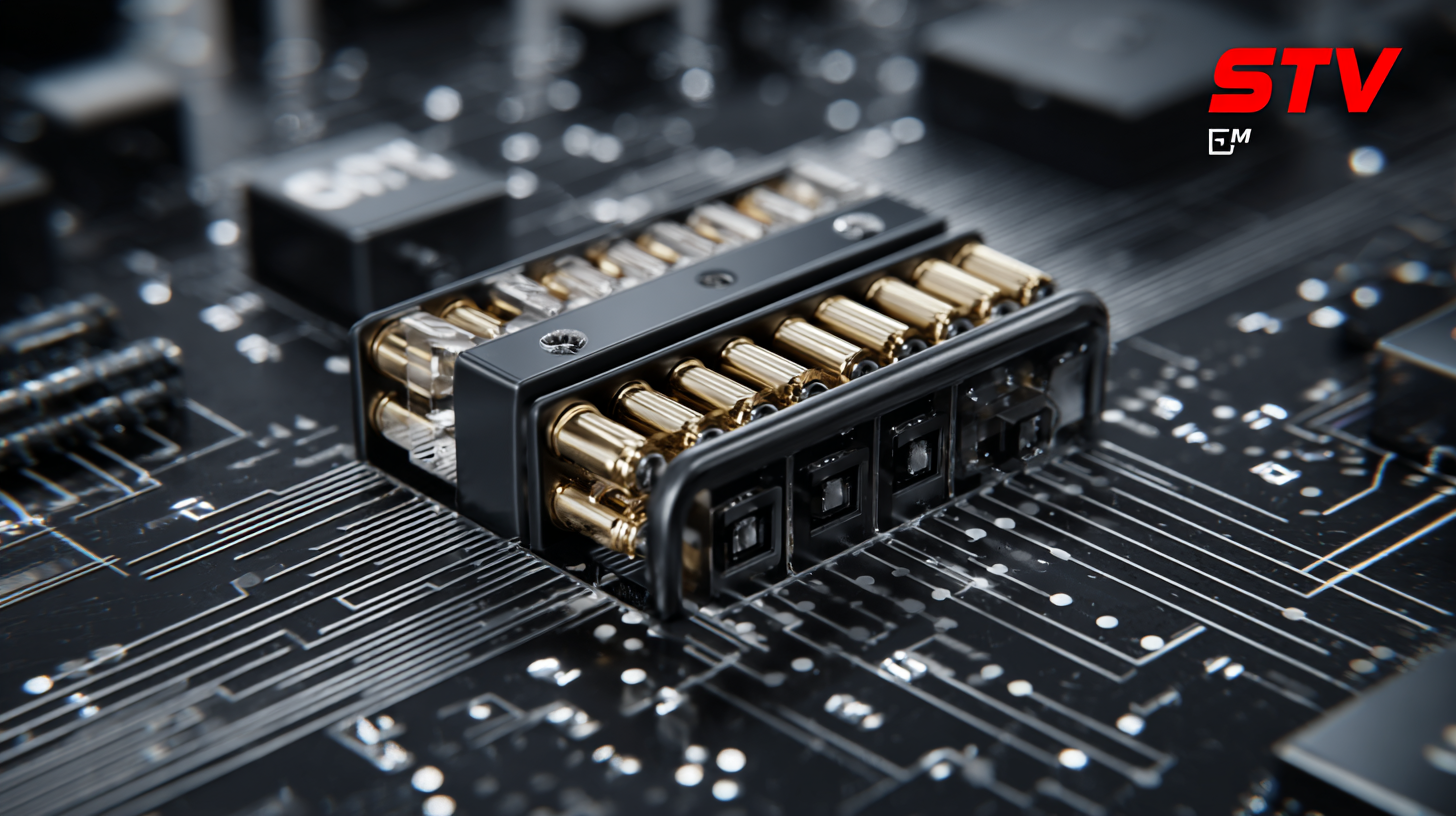

In today's competitive market, leveraging technology to enhance after-sales service efficiency and effectiveness is crucial for reducing repair costs associated with rectangular connectors. Implementing advanced diagnostic tools can streamline the maintenance process, enabling technicians to quickly identify issues and resolve them without unnecessary delays. For instance, using predictive analytics, companies can foresee potential failures before they occur, allowing for proactive maintenance that not only minimizes downtime but also reduces overall repair costs.

Furthermore, integrating customer relationship management (CRM) systems into after-sales processes can significantly improve customer satisfaction and loyalty. These platforms allow businesses to track service history and customer feedback, facilitating personalized service that meets specific client needs. Automation tools, such as chatbots and self-service portals, also empower customers to troubleshoot basic issues on their own, further alleviating the service team's workload and reducing operational costs. By harnessing technology in these ways, companies can ensure that their after-sales services are not just efficient, but also cost-effective, ultimately maximizing value for both the business and its customers.

Effective communication with customers regarding connector repairs is crucial for maximizing value and minimizing costs. According to a recent report by the International Electromechanical Commission, improper communication can lead to misunderstandings that contribute to an estimated 30% increase in repair costs. To counter this, companies should adopt a transparent approach. Keeping customers informed about the service process, potential costs, and timelines fosters trust and reduces anxiety, which can ultimately lead to more favorable outcomes.

Incorporating proactive communication strategies can also enhance customer satisfaction. A survey by the Customer Service Institute found that businesses that provide regular updates during the repair process see a 40% increase in customer satisfaction ratings. Offering detailed explanations of the repair process and any necessary parts can prevent post-service dissatisfaction. Furthermore, leveraging technology, such as automated messaging systems, ensures timely updates and keeps customers engaged, thereby reinforcing their loyalty and willingness to return for future services. Such best practices not only improve repair outcomes but also contribute positively to a company’s reputation in the competitive connector market.

| Tip | Description | Expected Cost Reduction (%) | Implementation Timeframe |

|---|---|---|---|

| 1. Regular Maintenance | Encourage regular checks and maintenance to avoid larger repairs. | 20% | Ongoing |

| 2. Customer Training | Provide training sessions for customers on proper usage and care. | 15% | 1 Month |

| 3. Quick Response Time | Establish a system for prompt response to service requests. | 10% | 1 Week |

| 4. Comprehensive Warranty | Offer an extended warranty that covers significant repairs. | 25% | 1 Month |

| 5. Inventory Management | Keep an adequate stock of spare parts to expedite repairs. | 30% | Ongoing |

| 6. Transparent Communication | Keep customers informed about repair costs and timelines. | 5% | Immediate |

| 7. Partner with Local Services | Collaborate with local service centers for faster repairs. | 15% | 2 Months |