News / Blog

How to Optimize Electronic Resistors for Improved Circuit Performance and Reliability

The optimization of electronic resistors is a critical factor in enhancing circuit performance and reliability, as highlighted in recent industry reports. According to a study by MarketsandMarkets, the global passive components market, which includes electronic resistors, is projected to reach $24.5 billion by 2025, growing at a CAGR of 5.7% from 2020. This growth underscores the increasing dependency on high-performance resistors in various applications, from consumer electronics to automotive and industrial systems.

As circuits become more complex, the demand for resistors that can provide stable performance under varying conditions has never been more significant. Engineers are now focusing on fine-tuning resistor specifications—such as tolerance, power rating, and thermal stability—to meet these challenges. This guide will delve into strategies for optimizing electronic resistors to ensure enhanced circuit functionality and longevity, addressing both current industry standards and future trends.

Strategies for Selecting High-Quality Electronic Resistors to Enhance Circuit Performance

When selecting high-quality electronic resistors, it's crucial to consider both the specifications and the application requirements. According to a report by the Electronic Industry Association, nearly 30% of circuit failures are attributed to resistor-related issues, underscoring the importance of choosing the right components. Key parameters such as tolerance, temperature coefficient, and power rating can dramatically influence overall circuit performance. For instance, resistors with a tolerance of 1% or better are recommended for precision circuits, as they ensure more accurate performance deviations.

In addition to specifications, environmental factors play a significant role in the selection process. Data from the International Electrotechnical Commission indicates that resistors operating in extreme temperatures or volatile conditions should have higher thermal stability to maintain reliability. Utilizing resistors with excellent heat dissipation capabilities can minimize the risk of failure, which is essential in high-performance applications. In the context of enhancing circuit reliability, investing in premium resistors might seem costlier initially but can lead to greater long-term savings by reducing maintenance costs and improving system longevity.

Analyzing Resistance Tolerance and Its Impact on Circuit Reliability in Electronic Applications

Resistance tolerance plays a crucial role in the performance and reliability of electronic circuits. According to the latest report by the Electronics Components Industry Association (ECIA), a tolerance of ±1% in resistors can enhance circuit integrity, reducing the risk of component failure in critical applications. This becomes especially significant in high-precision environments, such as medical devices and aerospace systems, where even minute variations can lead to operational discrepancies. As resistance tolerance decreases, this stability contributes positively to long-term reliability, ensuring that circuits can perform consistently over extended periods.

Moreover, circuit designers are increasingly recognizing the impact of materials and manufacturing processes on resistance tolerance. A study by the Institute of Electrical and Electronics Engineers (IEEE) indicated that utilizing high-quality materials, such as metal film resistors, can yield tolerances as low as ±0.1%. This precision not only leads to enhanced circuit reliability but also minimizes the effects of temperature fluctuations on performance. With the growing demand for high-performance electronics, optimizing resistance tolerance is no longer just a matter of cost but a vital component of circuit design aimed at achieving greater efficiency, longevity, and safety in electronic applications.

Optimization of Electronic Resistors for Circuit Performance

This bar chart illustrates the resistance tolerance levels for various resistor values used in electronic applications. Understanding tolerance is crucial for optimizing circuit performance and ensuring reliability in electronic designs.

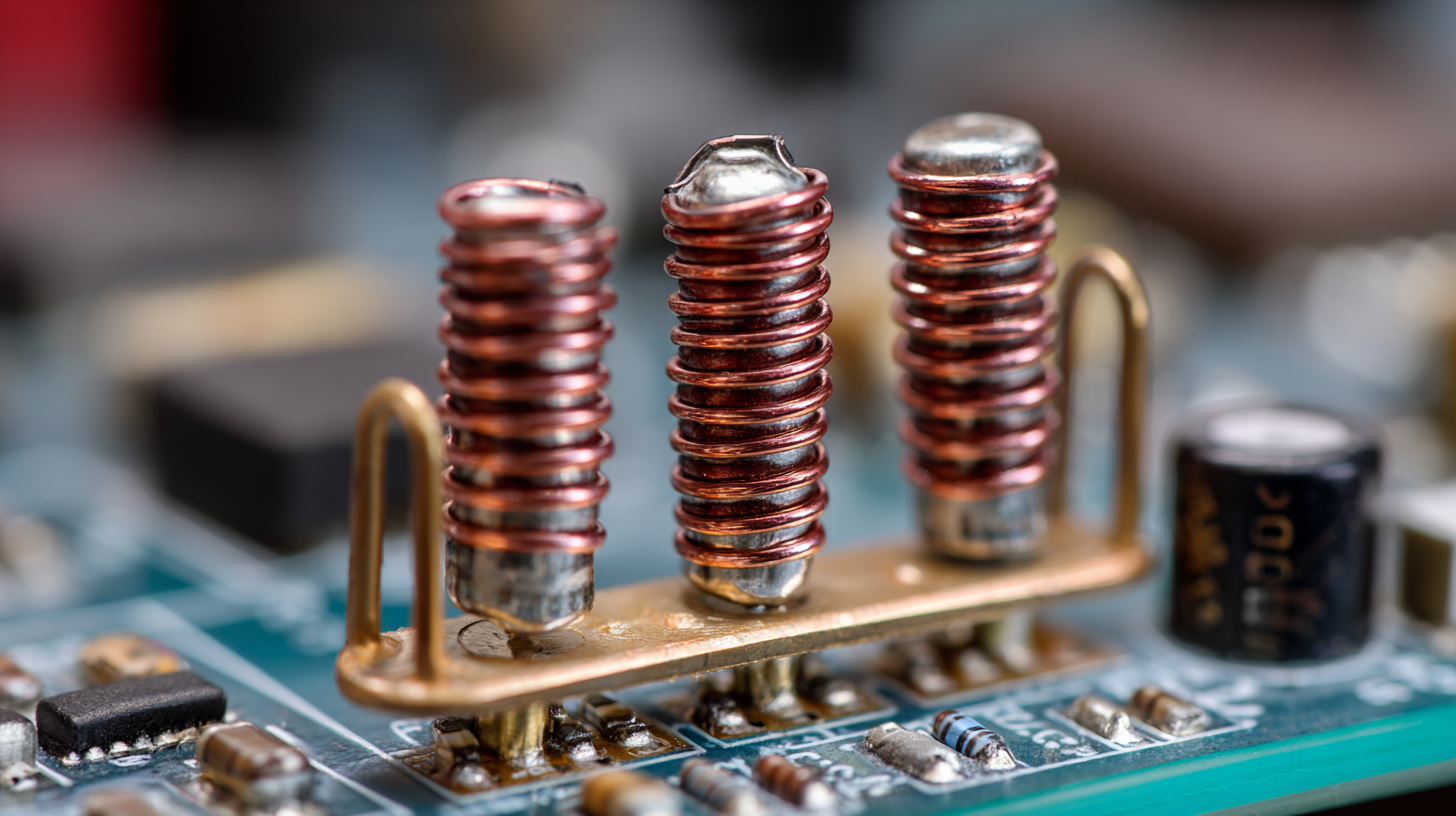

Implementing Power Rating Considerations for Optimizing Resistor Performance Under Load

When optimizing electronic resistors for improved circuit performance, one of the critical factors to consider is the power rating of the resistors under load. The power rating directly affects how resistors can dissipate heat without compromising their functionality and longevity. According to a study published by the International Electrotechnical Commission (IEC), resistors that operate consistently at or below 75% of their rated power can significantly enhance circuit reliability and performance. Overloading resistors can lead to thermal runaway, significantly decreasing their lifespan and causing potential circuit failures.

Tips: Always select resistors with power ratings that exceed your application's maximum load requirements. Implementing derating practices, where you operate your resistors at a lower percentage of their maximum rating, can prevent overheating and ensure stable performance. For high-frequency applications, consider using surface-mount technology (SMT) resistors, which can better handle heat dissipation due to their lower thermal mass.

Furthermore, it’s essential to evaluate the environmental factors that may influence resistor performance. High ambient temperatures or inadequate ventilation can decrease the effective power rating of resistors. An analysis from the Electronic Components Industry Association (ECIA) suggests incorporating thermal management strategies such as heatsinks or airflow to enhance the overall circuit reliability in demanding conditions.

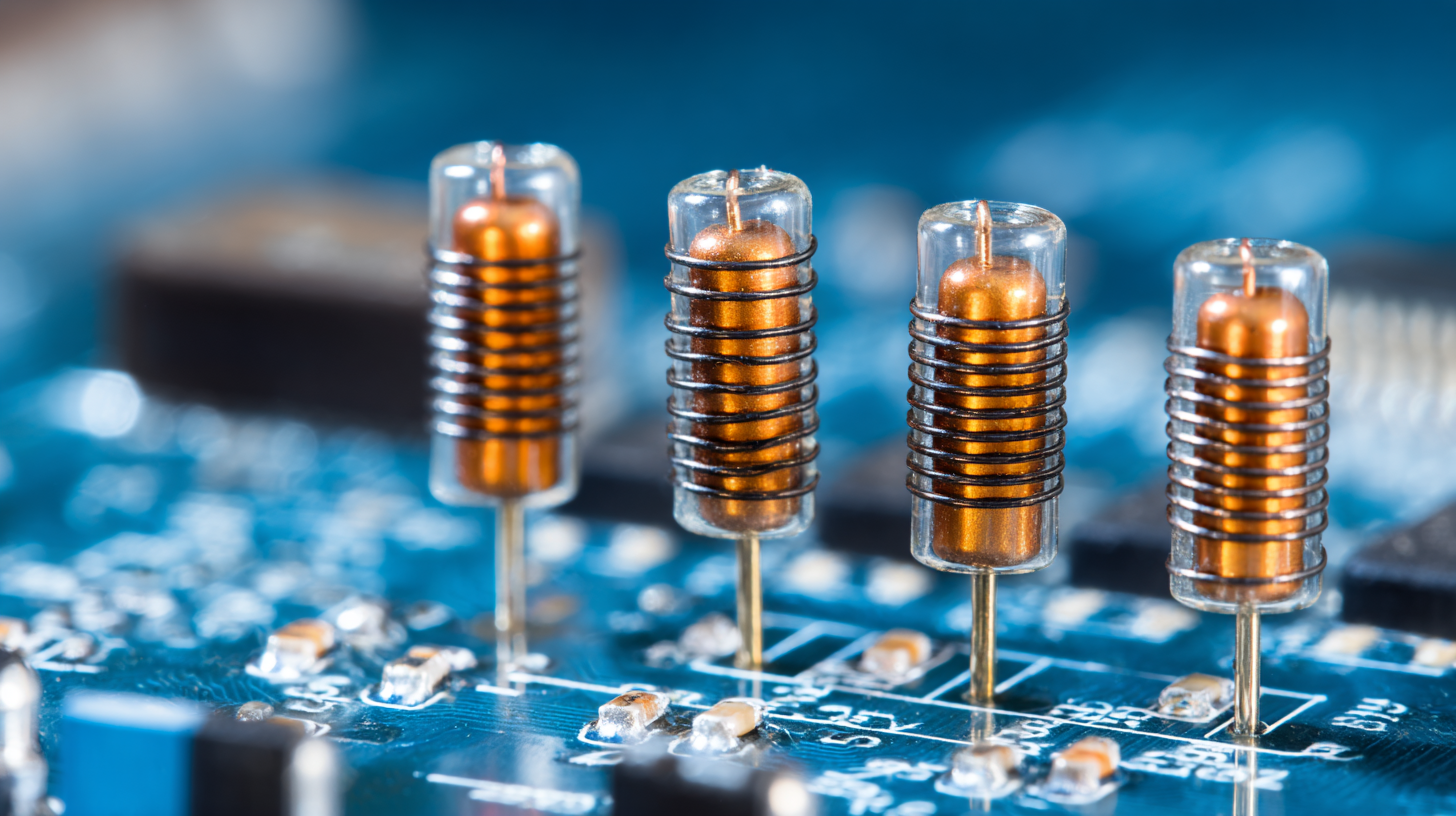

Utilizing Temperature Coefficients to Select Resistors for Improved Thermal Stability in Circuits

When designing electronic circuits, selecting the right resistors is critical for enhancing thermal stability. Understanding the temperature coefficient of resistors—which indicates how much the resistance changes with temperature—can help engineers make informed choices that improve both performance and reliability. Resistors with low temperature coefficients are preferable for applications exposed to varying environmental conditions, as they maintain consistent resistance values, minimizing the risk of circuit failure due to thermal fluctuations.

**Tips:** When selecting resistors, it's essential to consult the manufacturer’s datasheet to find the temperature coefficient that suits your application. Resistors with temperature coefficients in the range of ±50 ppm/°C are often ideal for precision circuits, while those in the range of ±100 ppm/°C may be suitable for general-purpose applications.

Additionally, choosing resistors with better thermal management properties can significantly enhance circuit performance. Consider using wire-wound or metal-film resistors, as they typically exhibit lower temperature coefficients compared to carbon-based options. This choice can result in more stable circuit operation, especially in high-power applications where heat generation is a concern.

**Tips:** Always assess the power rating and thermal characteristics of the resistor when designing your circuit. Utilizing heat sinks or mounting resistors on a PCB with adequate copper area can further improve heat dissipation and thermal stability.

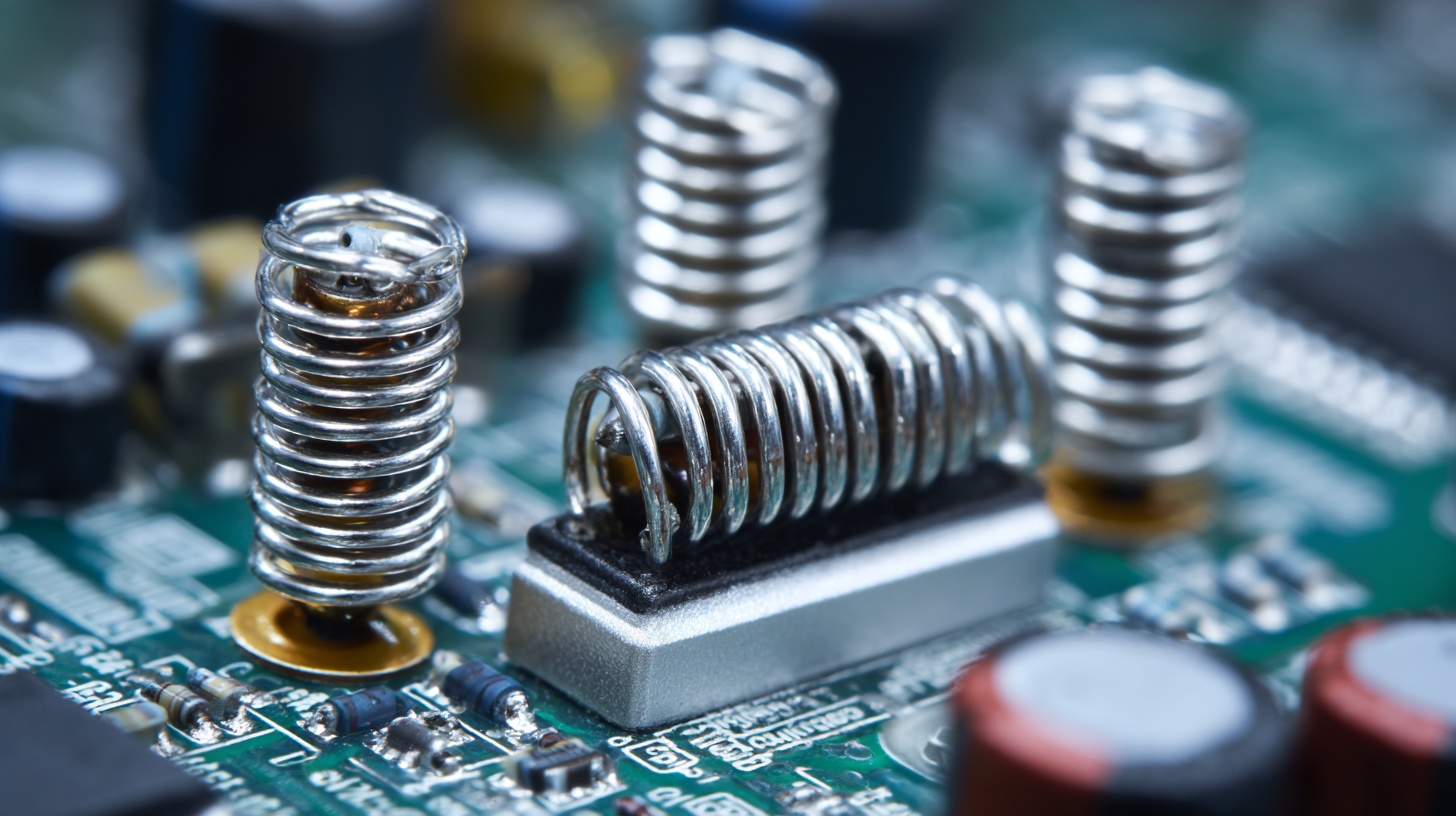

Exploring the Role of Resistor Packaging Technologies in Enhancing Performance and Reliability

Resistor packaging technologies play a pivotal role in enhancing electronic circuit performance and reliability. As circuits become increasingly compact and complex, the demand for resistors that can withstand higher temperatures and provide consistent performance becomes critical. According to a recent report by MarketsandMarkets, the global resistor market is expected to grow at a CAGR of 4.5% from 2021 to 2026. This growth is partly driven by advancements in packaging techniques that improve thermal management and reduce parasitic effects.

One effective strategy is the use of surface mount technology (SMT) packages, which help lower the impedance and improve signal integrity. Choosing the right packaging can also minimize the risk of mechanical stress during assembly, enhancing the resistor's longevity. For instance, epoxy resin encapsulation is increasingly popular due to its ability to protect components from moisture and environmental factors, which can severely impact performance and reliability.

**Tips:** When selecting resistors, consider those with advanced packaging forms like chip-led resistors or thick-film technology, which offer better heat dissipation. Additionally, ensure compatibility with your specific circuit layout to avoid potential issues with signal degradation. Lastly, always verify the manufacturer's specifications on thermal resistance and power ratings, as this can significantly influence your circuit's overall performance.

How to Optimize Electronic Resistors for Improved Circuit Performance and Reliability - Exploring the Role of Resistor Packaging Technologies in Enhancing Performance and Reliability

| Parameter | Value | Impact on Performance |

|---|---|---|

| Resistance Value (Ω) | 1k | Stable performance at high frequencies |

| Power Rating (W) | 0.25 | Prevents overheating and improves reliability |

| Temperature Coefficient (ppm/°C) | 50 | Minimizes drift in critical applications |

| Package Type | SMD | Improves thermal management and reduces board space |

| Voltage Rating (V) | 50 | Ensures safe operation in high voltage environments |