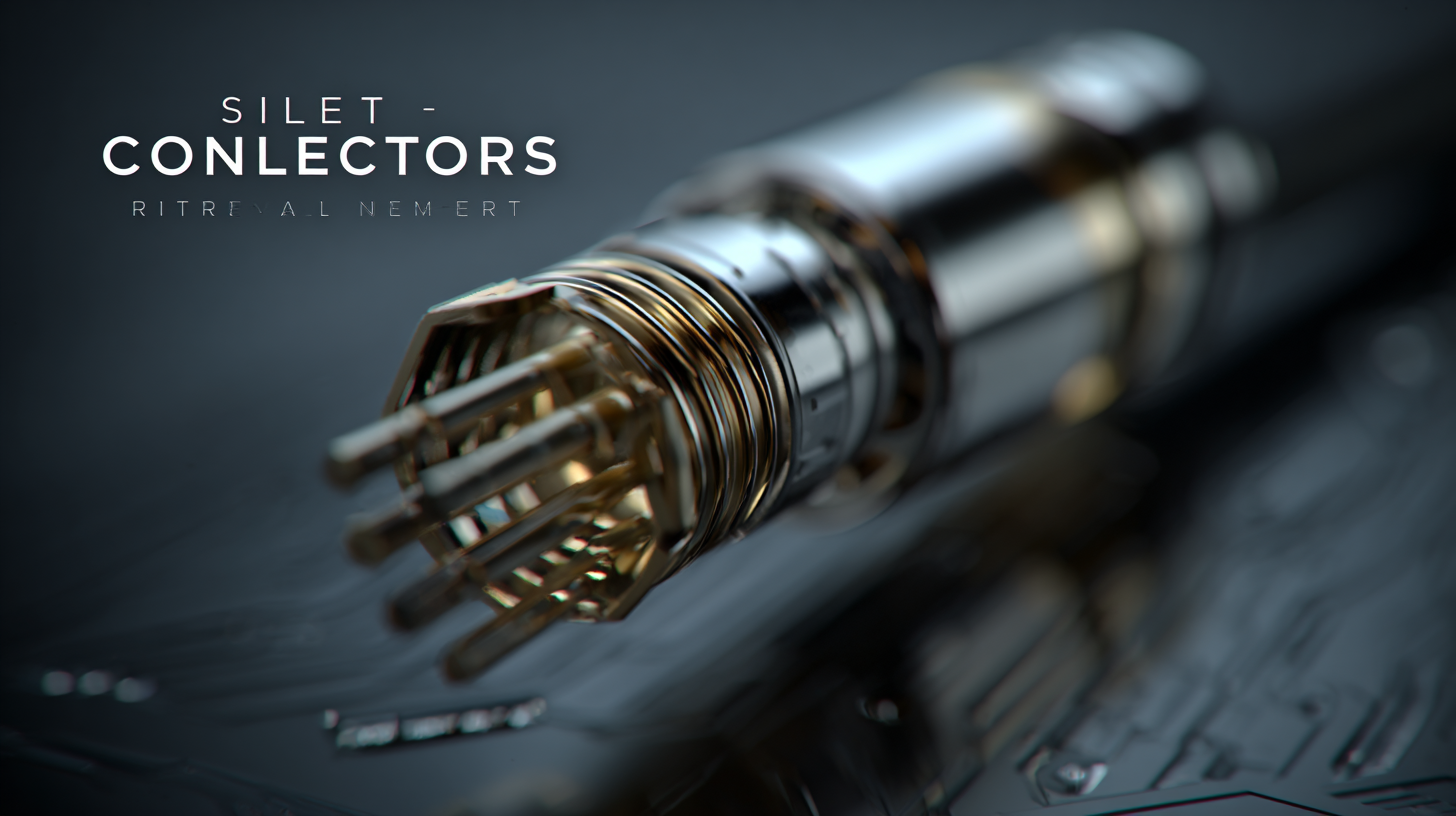

In today's rapidly evolving technological landscape, selecting the right components for your projects is paramount, and circular connectors play a crucial role in ensuring robust and reliable connections. According to a report by ResearchAndMarkets, the global circular connectors market is projected to reach approximately $XX billion by 2025, with a compound annual growth rate (CAGR) of XX% from 2020 to 2025. This growth is driven by the increasing demand for enhanced connectivity in various sectors, including automotive, aerospace, and telecommunications. However, with the plethora of options available, it is vital to address the challenges associated with industry production standards and connector types. Understanding these complexities is essential for engineers and designers striving to make informed decisions that meet their specific project needs and maintain high performance and safety standards.

When selecting circular connectors for your project, there are several crucial factors to consider. One primary aspect is the compatibility of the connectors, particularly the issue of cross-mating, identified as a significant problem in solar installations. The ability to connect different manufacturers’ connectors can greatly affect the efficiency and reliability of the system. According to a recent study, improper mating contributes to a significant percentage of installation issues, emphasizing the need for standardized connector designs that enhance compatibility and minimize the risk of failure.

When selecting circular connectors for your project, there are several crucial factors to consider. One primary aspect is the compatibility of the connectors, particularly the issue of cross-mating, identified as a significant problem in solar installations. The ability to connect different manufacturers’ connectors can greatly affect the efficiency and reliability of the system. According to a recent study, improper mating contributes to a significant percentage of installation issues, emphasizing the need for standardized connector designs that enhance compatibility and minimize the risk of failure.

Another important factor is the environmental conditions the connectors will face. Choosing connectors that are rated for the specific parameters of your project, such as temperature extremes, humidity, and exposure to chemicals, will ensure durability and longevity. Industry reports indicate that connectors designed for harsh environments can extend their operational life by up to 50%, which is critical for minimizing future maintenance costs and project downtime. Therefore, conducting a thorough assessment of your project needs against these factors will guide you in selecting the most suitable circular connectors, ultimately leading to a more successful and efficient project outcome.

When selecting the best circular connectors for your project needs, it’s essential to understand the different types available and their specific applications. Circular connectors are widely used across various industries, including aerospace, automotive, and telecommunications, due to their robust design and reliability. According to a recent report by Markets and Markets, the circular connector market is projected to grow from USD 3.4 billion in 2021 to USD 5.4 billion by 2026, reflecting the increasing demand for advanced connectivity solutions.

There are several types of circular connectors, each designed for specific functions. For instance, military-grade circular connectors are engineered to withstand harsh environmental conditions, making them ideal for defense and aerospace applications. In contrast, automotive circular connectors are tailored to endure vibrations and temperature fluctuations common in vehicles. Furthermore, standard circular connectors, which can be found in everyday electronic devices, often come with various pin configurations depending on the required strength and data transmission capabilities. Understanding the unique applications of these connectors is crucial for optimizing performance and ensuring the longevity of your project.

When selecting circular connectors for your project, understanding key specifications is crucial for ensuring optimal performance. Key metrics such as contact resistance, ingress protection (IP) ratings, and temperature range can significantly influence the reliability and longevity of the connectors. According to a report from the Markets and Markets Research, the global circular connector market is projected to grow to $4.07 billion by 2026, highlighting the increasing importance of these components in various applications, from automotive to telecommunications.

Contact resistance, for instance, is vital for maintaining signal integrity. Quality connectors typically exhibit a resistance of less than 5 milliohms, ensuring minimal power loss and heat generation. Furthermore, an optimal IP rating, such as IP67, indicates a connector's ability to withstand dust and water immersion, which is essential for outdoor or harsh environment settings. Additionally, temperature ranges between -40°C to 125°C are critical for connectors used in extreme conditions. Understanding these specifications not only aids in selecting the right connector but also contributes to the overall success and reliability of the project.

Selecting the right circular connectors for your project can be a daunting task, especially if you overlook common pitfalls. One frequent mistake is failing to consider the environmental conditions where the connectors will be used. High humidity, extreme temperatures, or exposure to corrosive elements can drastically affect performance and longevity. Always check the material specifications and ratings to ensure the connectors will withstand their intended environment.

Another common error is neglecting to pay attention to the electrical specifications. Choosing a connector based solely on size or aesthetics without considering current rating, voltage requirements, and compatibility with your specific application can lead to inefficiencies and potential failure. It's crucial to conduct thorough research on the electrical characteristics to prevent device malfunction, which can be costly and time-consuming to rectify.

Additionally, project managers often overlook the importance of compatibility with existing systems. Using connectors that aren't standardized or that require specific tools for installation can complicate assembly and increase labor costs. Always verify that selected connectors align with the infrastructure already in place, ensuring seamless integration and operational efficiency throughout your project.

When selecting circular connectors for your project, ensuring compatibility with existing systems and components is crucial. Begin by assessing the technical specifications of your current setup, including pin configuration, voltage ratings, and environmental factors like temperature and moisture levels. This will not only help you identify the right connector type but also guarantee seamless integration with your existing electrical or data systems.

Moreover, pay attention to the materials used in both the connectors and the interfaces they will interact with. The choice of materials can significantly impact durability and performance—corrosion-resistant options may be necessary if the connectors will be exposed to harsh conditions. Additionally, consulting with manufacturers about standardization can lead to more efficient sourcing of components, reducing the risk of compatibility issues down the line. Engaging with technical support or customer service representatives can further clarify any concerns and provide valuable insights tailored to your specific project requirements.

| Criteria | Details |

|---|---|

| Connector Type | Circular, Radial, or D-Sub |

| Pin Configuration | Number of Pins and Layout |

| Material | Plastic, Metal, or Composite |

| Environmental Rating | IP65, IP67, or IP68 |

| Voltage Rating | Low, Medium, or High Voltage |

| Current Rating | 1A, 5A, or 10A Options |

| Termination Style | Solder, Crimp, or PCB Mounted |

| Compatibility | Check with Existing Systems |