News / Blog

Essential Tips for Choosing the Right Electronic Capacitors for Your Projects

In the rapidly evolving landscape of electronics, selecting the right electronic capacitors is crucial for the success of any project. According to a recent market analysis report by Research and Markets, the global market for electronic capacitors is projected to reach $26.1 billion by 2026, highlighting their fundamental role in modern electronic design. As technology advances, the specifications and requirements for these components continue to grow ever more complex, necessitating a careful approach to selection.

Renowned industry expert Dr. Emily Chen, a leading figure in capacitor technology, emphasizes the importance of understanding the intricacies of electronic capacitors: "Choosing the right capacitor is not just about meeting the specifications; it’s about understanding the entire system requirements." This insight underscores the importance of considering factors such as capacitance, voltage rating, and physical size, which can significantly affect the performance and reliability of the final product.

As engineers and designers face an array of options, the process of choosing electronic capacitors can be daunting. However, by leveraging expert recommendations and industry standards, professionals can make informed decisions that enhance the efficacy of their electronic projects and contribute to innovation in the field.

Understanding the Different Types of Electronic Capacitors Available

When selecting electronic capacitors for your projects, it is crucial to understand the

different types available, as each serves specific

functions and applications. The most commonly used capacitors include ceramic,

electrolytic, tantalum, and film capacitors.

Ceramic capacitors are favored for their stability and reliability, making them ideal for

high-frequency applications. They come in various voltage ratings and capacitance values,

allowing flexibility in design.

Electrolytic capacitors, characterized by their polarized nature, are widely used for

filtering and bulk energy storage

in power supply applications. Their high capacitance values make them suitable for energy-intensive

applications, but they generally come with higher leakage currents and limited lifetime.

On the other hand, tantalum capacitors offer higher capacitance in smaller sizes with

excellent ESR characteristics, but caution is required as

they are sensitive to voltage overload.

Film capacitors are known for their low losses and

excellent stability over a broad frequency range, making them appropriate for signal coupling

and decoupling tasks. Each type of capacitor has unique characteristics, and

understanding these differences is essential for making

informed choices that will enhance the performance and reliability of your electronic projects.

Selecting the right capacitor involves considering factors such as

application requirements, size constraints, and

environmental conditions to ensure optimal performance.

Key Specifications to Consider When Selecting Capacitors for Your Project

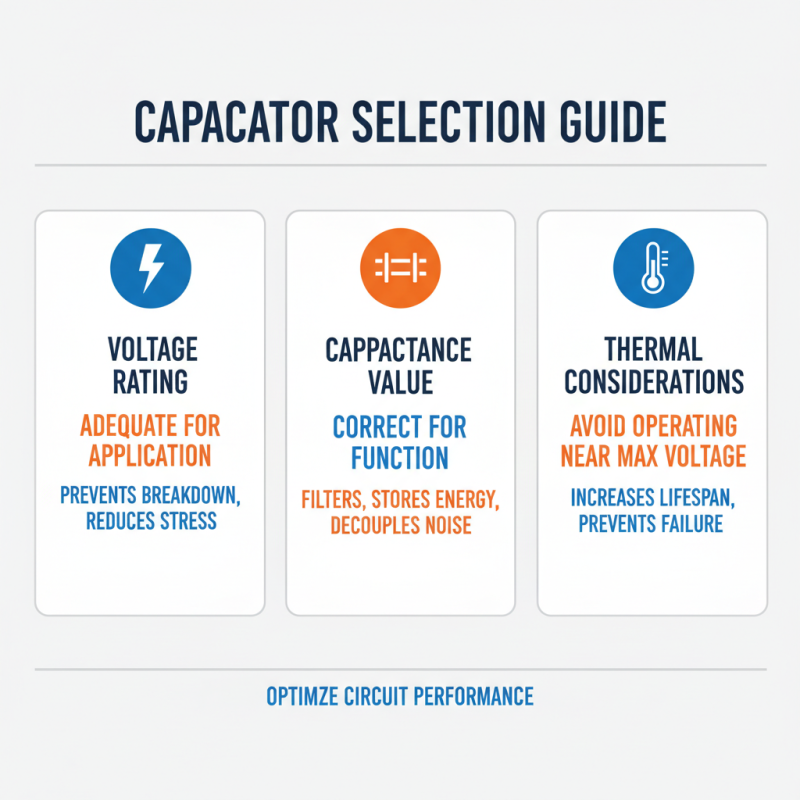

When selecting electronic capacitors for your projects, understanding key specifications is crucial to ensuring optimal performance. Initially, the voltage rating must be considered; it defines the maximum voltage the capacitor can withstand without failing. Choose a capacitor with a voltage rating higher than the maximum voltage in your application to ensure reliability and safety. Additionally, the capacitance value, measured in farads (F), dictates the capacitor's ability to store energy. Selecting the correct capacitance will depend on your project's specific requirements, whether for energy storage, filtering, or timing.

Another important factor is the equivalent series resistance (ESR). ESR impacts the efficiency and heat generation of the capacitor when used in circuits, especially in power supply applications. A lower ESR is generally preferable for high-frequency operations, as it can lead to reduced power losses. Furthermore, the temperature coefficient of the capacitor material influences performance under varying thermal conditions. Capacitors are available in different dielectric materials, each with unique voltage, temperature stability, and frequency characteristics, making it essential to match these properties with your project's environmental conditions and performance needs.

Essential Tips for Choosing the Right Electronic Capacitors for Your Projects

This chart illustrates the capacitance values of various types of electronic capacitors commonly used in projects. Understanding these values is essential for selecting the right capacitor for your specific needs.

Factors Affecting Capacitor Performance in Various Applications

When selecting electronic capacitors for specific applications, understanding the factors that affect their performance is essential. One critical factor is the capacitor's voltage rating, which must be adequate for the application to prevent breakdown and potential failure. Operating a capacitor consistently near its maximum voltage can lead to thermal stress and a reduced lifecycle. Additionally, the capacitance value itself plays a significant role; selecting a capacitor with the correct capacitance ensures that it can effectively filter signals, store energy, or decouple noise as intended in the circuit design.

Temperature and frequency are also vital considerations that influence capacitor performance. Different types of capacitors exhibit varying performance characteristics at different temperatures, which can affect their capacitance and equivalent series resistance (ESR). In high-frequency applications, the parasitic effects become more pronounced, and the choice of capacitor bearing a low ESR is crucial for maintaining signal integrity. Therefore, understanding the environmental factors and the specific electrical requirements of the project is paramount to ensure optimal capacitor selection that aligns with the intended application.

Best Practices for Sourcing Quality Capacitors from Suppliers

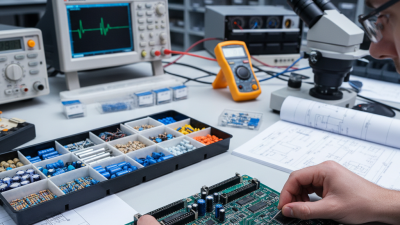

When sourcing quality electronic capacitors for your projects, it's crucial to establish relationships with reputable suppliers. Begin by conducting thorough research to identify vendors who specialize in capacitors and have a solid track record in the industry. Look for suppliers that offer detailed product specifications and datasheets, allowing you to verify the performance and suitability of their capacitors for your specific applications. Engaging with suppliers that prioritize transparency can help you assess their quality control processes and standards.

Additionally, request samples before committing to larger orders. This practice enables you to evaluate the components in your actual circuits and assess their reliability under your operating conditions. Pay attention to lead times and the ability of the supplier to meet your demands consistently. Establishing communication channels for technical support or inquiries is also vital, as this can enhance your experience and ensure you can address any concerns that may arise during your project development. By prioritizing trustworthy suppliers and maintaining open lines of communication, you can optimize the quality of capacitors in your projects.

Common Mistakes to Avoid When Choosing Capacitors for Electronics Projects

When selecting electronic capacitors for your projects, it's crucial to avoid common mistakes that can compromise your circuit's performance. One significant error is overlooking the capacitor's voltage rating. Choosing a capacitor with a voltage rating that is too close to the actual voltage in your circuit can lead to failure, potentially damaging other components. Always select capacitors with a voltage rating significantly greater than your operating voltage to ensure reliability and prevent breakdowns.

Another common pitfall is ignoring the capacitor's capacitance value. Often, engineers underestimate or miscalculate the capacitance needed for a specific application. This can result in insufficient filtering, unintended oscillations, or unanticipated circuit behavior. To prevent this mistake, ensure you fully understand the requirements of your project and verify the capacitance with proper calculations or simulation tools. Additionally, consider temperature and frequency characteristics, as these factors can significantly impact a capacitor's performance in practice. By being mindful of these common errors, you can select the right capacitors that enhance the reliability and functionality of your electronics projects.

Related Posts

-

Why Electronic Capacitors Are Essential for Modern Electronics

-

How to Choose the Right Resistors and Capacitors for Your Electronics Projects

-

How to Optimize Electronic Resistors for Improved Circuit Performance and Reliability

-

The Hidden Importance of Active Components in Everyday Products

-

Why Electronics Products are Essential for Modern Living and How to Choose the Best Ones

-

2025 Top 5 Essential Electronic Parts You Can't Afford to Miss